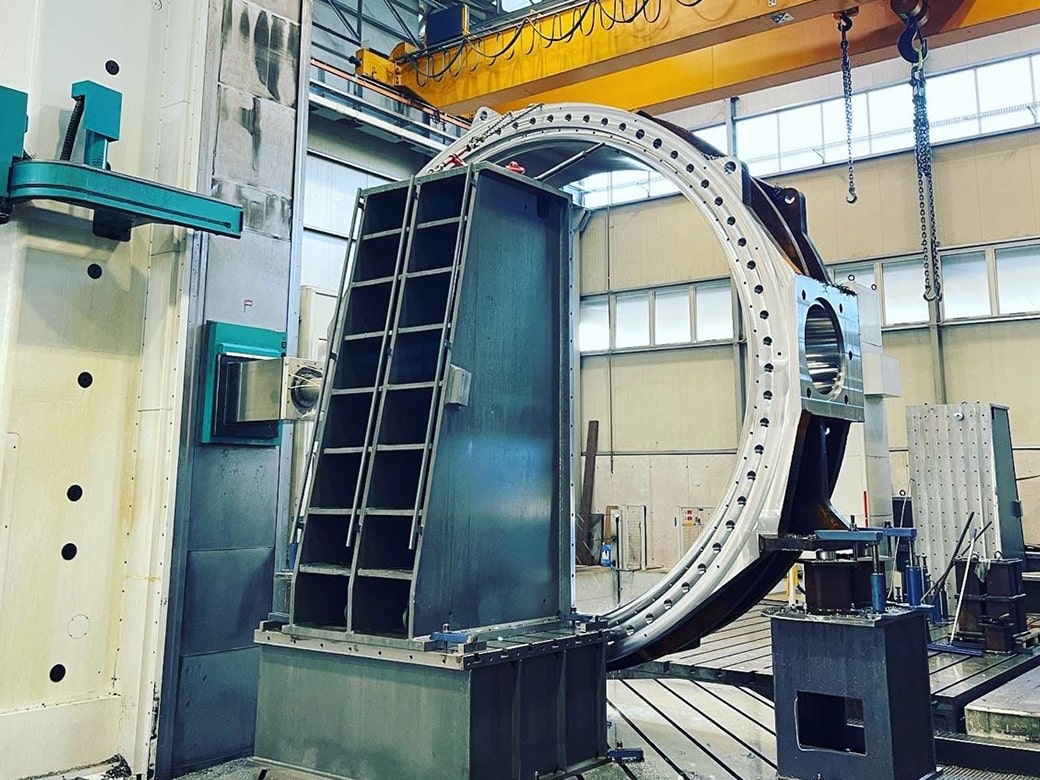

Preet Brothers Limited | Metal Refining AOD Converters | A Preet Enterprises

PREET manufactures wide range of Argon Oxygen Decarburization (AOD) Converter customised to fit the needs of our clients. We use superior-grade stainless steel and other basic components that are procured from reliable vendors of the industry to manufacture AOD converters. Most of the stainless steel in the world is made using the Argon Oxygen Decarburization (AOD) process. AOD is an economical way to produce stainless steel. It is part of a duplex process in which scrap or virgin raw materials are first melted in an electric arc furnace (EAF) or induction furnace. The molten metal is then decarburized and refined in a special AOD vessel to less than 0.05% carbon. The key feature in the AOD vessel is that oxygen for decarburization is mixed with argon or nitrogen inert gases and injected through submerged tuyeres. This argon dilution minimizes unwanted oxidation of precious elements contained in specialty steels, such as chromium.

FUNCTION

Metal refining Converters is used for making stainless steel of various grades. Liquid steel produced from Induction Furnace or Electric Arc Furnace is poured into ladle & is subsequently poured into the converter with the help of E.O.T. Crane. Before pouring the liquid metal, some important parameters like its temperature & chemical composition are analysed. Based on this analysis, liquid steel is refined by addition of required alloys & fluxes. Inert gases are also blown into the converter simultaneously.

APPLICATION

Decarburization | To make Stainless Steel grades, Alloy Steel Economically by using High Carbon Fe Alloy and Mild Steel Scrap/Sponge Iron | This process is Air – Oxygen – Inert gas Decarburization (AOD) process, for making Stainless Steel out of mild steel, Mild Steel out of high Cast Iron Melt, and alloy steel economically | PLC based Gas Mixing Station of Metal Refining AOD Converters gives flow measurements compensated for pressure and temperature variation. This avoids, “over oxidation” of liquid metal | Imported Transducer used for accurate flow and pressure measurement in Gas Mixing Station of MRK enables high turn down ratio which results in low process gas and refractory consumption and high recovery of alloying elements | Use of dry air (-80o C dew point) as process gas reducing the cost of production.

ADVANTAGES OF PREET Metal Refining AOD Converters

PLC based PREET Metal Refining AOD Converters process control software uses unique blowing pattern selection system which reduces oxygen, nitrogen consumption and idle time during process | Fully suspended drive mechanism to minimize vibration to the foundation and surrounding | By-pass valve for safe operation | Overall process display on touch screen HMI | Recording facility helps improved traceability, quality, reliability and repeatability | Printout of recorded data of gases and pressure help in monitoring each heat making process and composition | Online costing of heat can be monitored from remote places.

MECHANICAL PARTS

Boiler quality MS plates are used for fabrication of PREET Metal Refining AOD Converters vessel which are stress relieved and Ultrasonically tested welding joints | Dual brakes provide greater safety. One brake is thruster type while other is spring applied air retract disk brake, which has faster response time | Tunion ring and shaft are specially fabricated from special alloys and all welded portions are Completely X-ray scanned. Fume extraction and pollution control system is provided with PLC based controls of valves | Planetary gear box has been used to optimize space | Feeding system for continuous charging of Ferro alloys and scrap at a controlled ratio |Torque arm is used to absorb vibration on foundation & gear box | Jerk – less rotation with angular position encoder.

PREET BROTHERS LIMITED | LONG PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE

Preet Brothers Limited | Long Product Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects with annual capacity up to 1,000,000 Tons like: Rebar Rolling Mills, Wire Rod Rolling Mills, Bar Rolling Mills, Light Section Rolling Mills, Medium Section Rolling Mills, Heavy Section Rolling Mills. Besides complete plants Preet Brothers Limited | Long Product Hot Rolling Mill Division also under-take custom built design equipment’s based on the latest technology for various rolling mill equipment and systems like Rebar Rolling Mills | SBQ Rolling Mills | Wire Rod & Bar Rolling Mills | Small Section Rolling Mills | Medium Section Rolling Mills | Heavy Section Rolling Mills On Turnkey Bases (EPC & EP&S). Reheating Furnaces for Rolling Mills | Housingless stands for Hot Rolling Mills | Convertible Housingless Stands for Hot Rolling Mills | Universal Housingless Stands for Section Rolling Mills | Cantilever Stands for Hot Rolling Mills | Wirerod Mono-Block for Hot Rolling Mills | Sizing Mills for Hot Rolling Mills | Crank Shears for Hot Rolling Mills | Flying Shears for Hot Rolling Mills | Crop & Cobble Shears for Hot Rolling Mills | Crank cum Flying Dividing shears for Hot Rolling Mills | Thermo-processing units (TMT Plants) for Hot Rolling Mills | Harden Ground Gears & Gear boxes & Profile Ground Gears & Gear boxes | Entry and Exit Roller Guides Harden & Profile Ground Gears & Gear boxes | Slitting Guide boxes for 2 / 3 / 4 / 5 / 6 slitting Harden & Profile Ground Gears & Gear boxes | Sliding apron (Braking Slide) Rake type Cooling beds Harden & Profile Ground Gears & Gear boxes | Cold Shears of various sizes (150-1500Tons) | Dispatch & Bundling systems | Bar counters | Magnetic Stackers for Section handling | Single / Multi Groove Straighteners for on-line & off-line application in section rolling mill | Hot Saws & Cold Saws for Section Rolling Mill | Roll Changing Robots & Tilters for Rebar Rolling Mills | Preet Brothers Limited Roll-pass designs for slitting, angles, channels, I-beams & H-beams. Latest technology and high productivity of our plants: Guided by these concepts, we supply a complete scope of any green-field rolling mill for long products, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. Technical department @Preet Brothers Limited, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

AOD Converter Shop

AOD Convertor Shop

AOD Convertor

CCM for Melt Shop

Charging System for AOD