DKD Ikjot United | CNC Machines Building Division CNC ROLL NOTCHING & BRANDING MACHINE | Notch Master | A Preet Enterprises

CNC ROLL NOTCHING & BRANDING MACHINE:

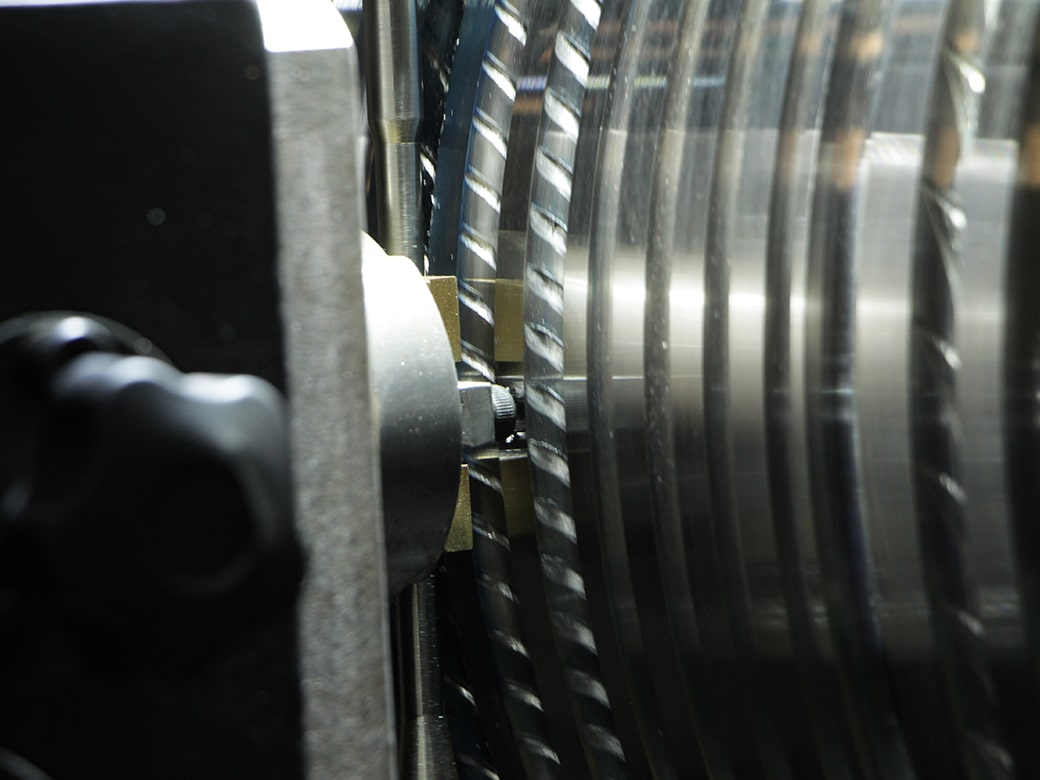

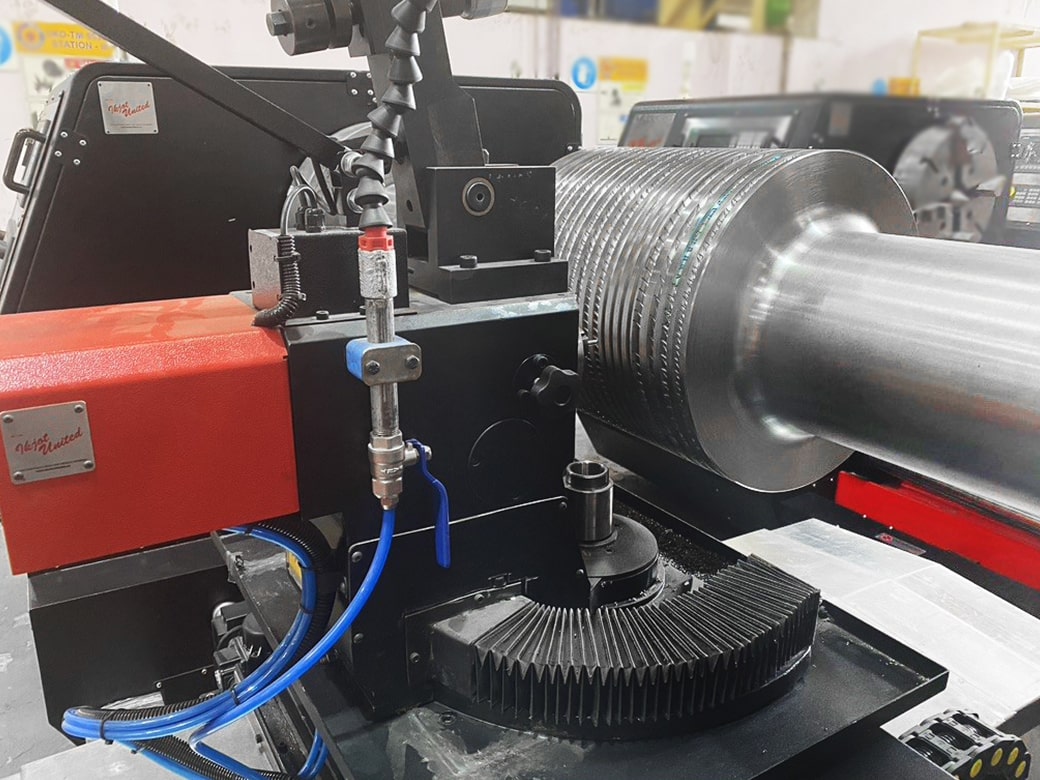

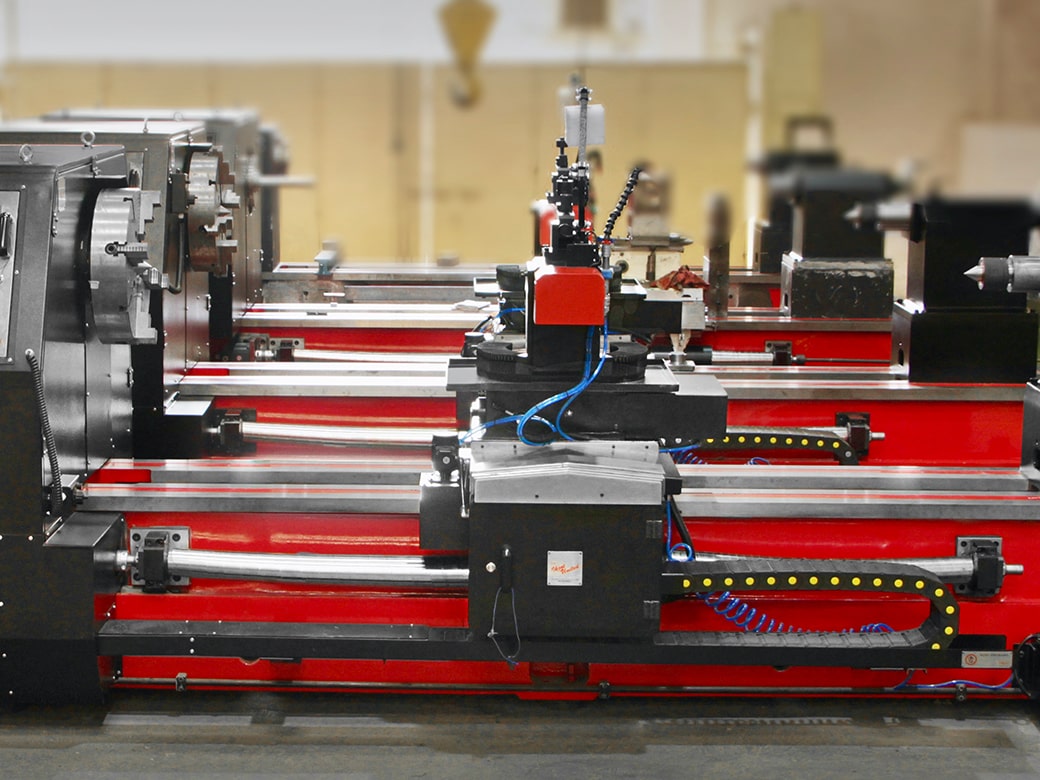

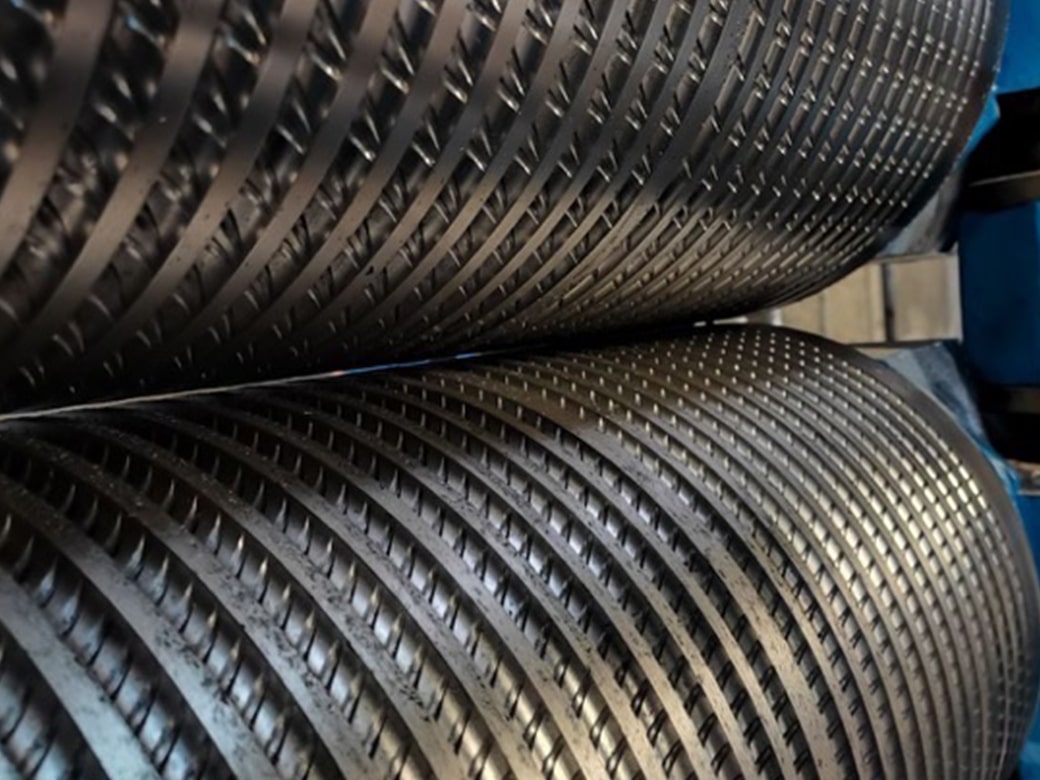

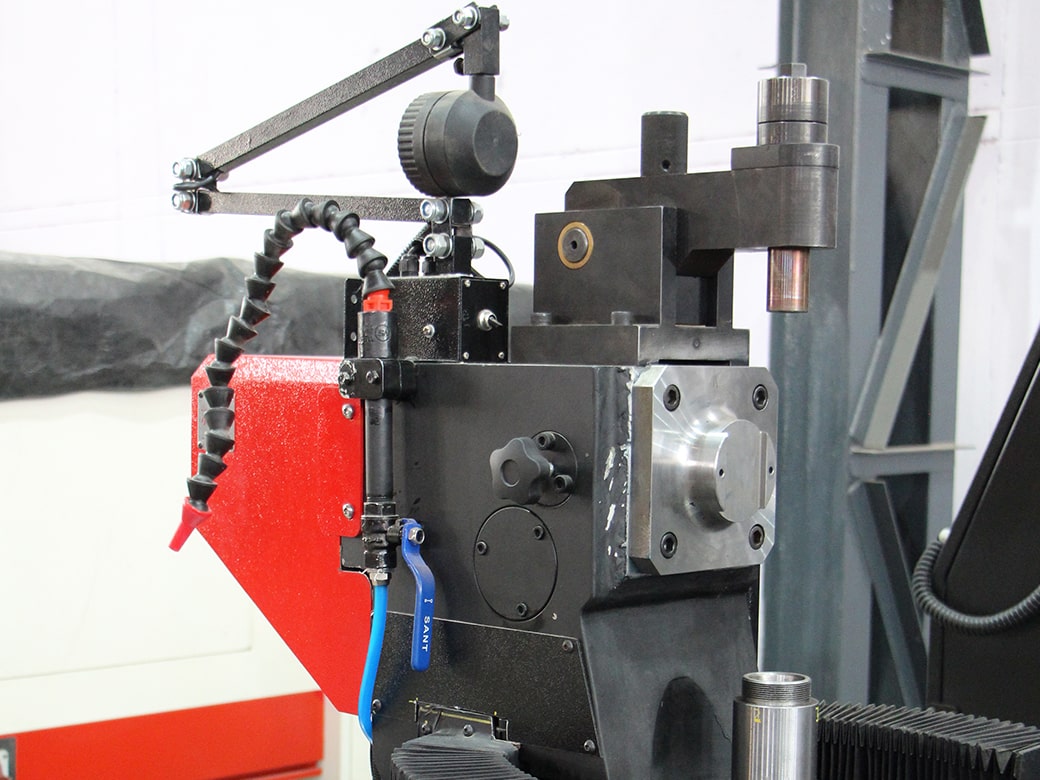

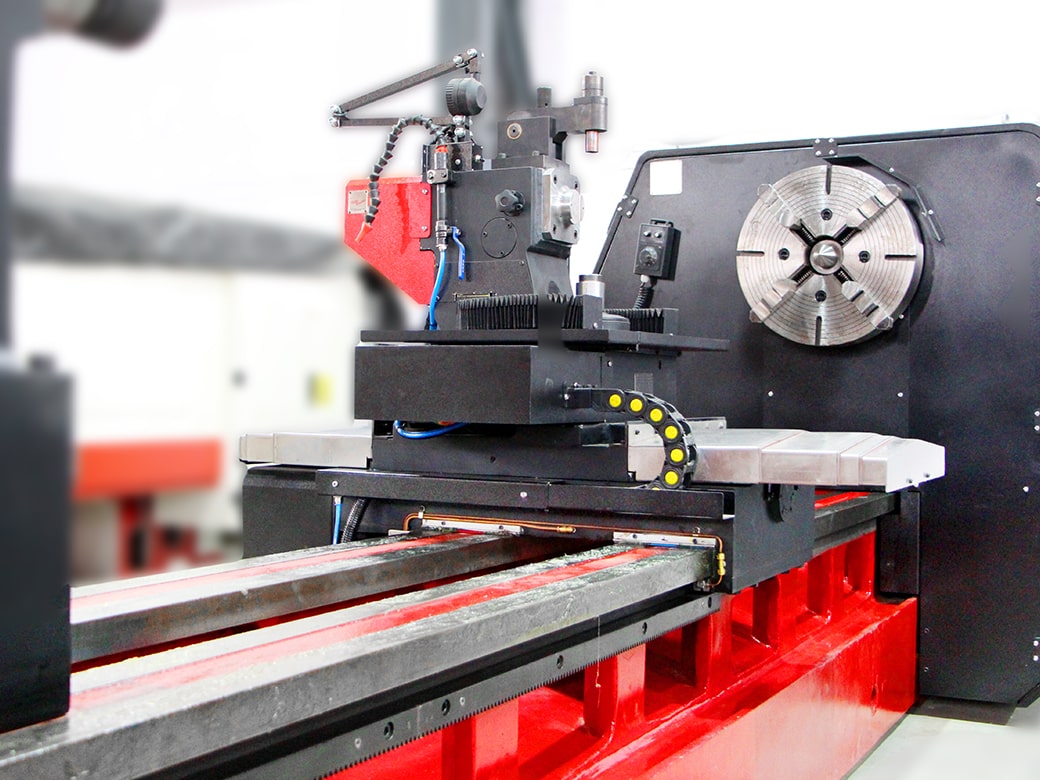

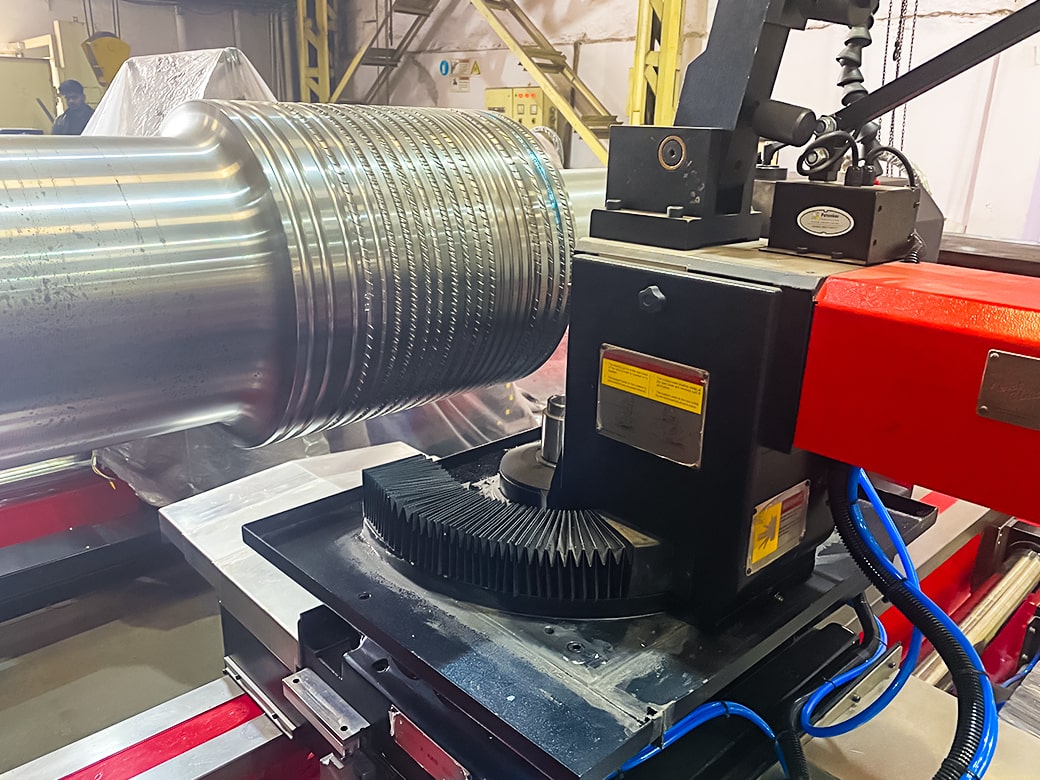

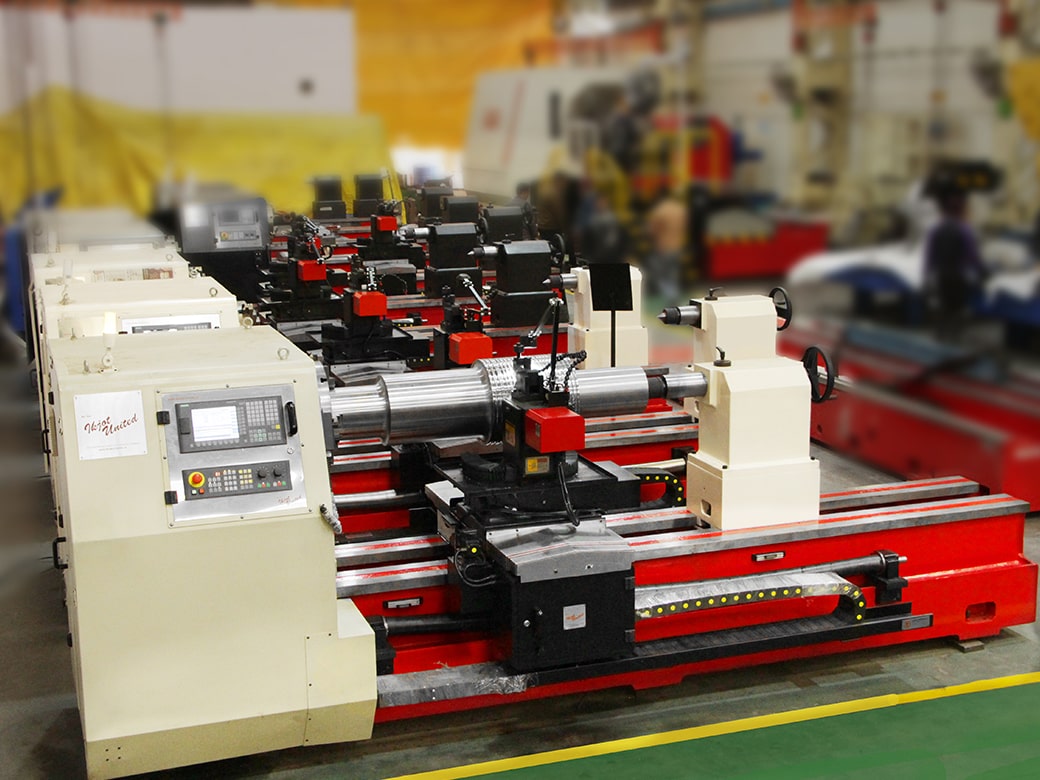

DKD Ikjot United CNC roll lathes are with hardened & ground guide way ensure the high accuracy. Rectangular heavy bed & saddle with Turcite-B guarantee long lasting accuracy. Independent big electrical box with nice cooling guarantees the work well in Southeast Asia. High rigid precision ball screws ensure the transmission for precision positioning and automatic operation. CNC system performs 4 axes control and 3 axes simultaneous movement. Freely cut crescent notches in any rotation direction and lead angle. Automatically engrave logo, symbols and specification codes in any position. Easy operation & programming come true by our special R&D software for this machine. Manufacturing rebar requires the milling of notches into the grooves of rolls and roll rings. A special focus is put on the combination of highest quality results and shortest machining times. Notch milling machines by DKD Ikjot United are the perfect solution for this application. They are characterized by a machine concept which guarantees extreme stiffness. That ensures high productivity even with very hard materials. Notch milling machines made by DKD Ikjot United have been an integral part of many roll shops around the world for many decades. In addition to the specialized notch milling machine, DKD Ikjot United also offers lathes and groove grinders equipped with a notch milling unit. Modular machine concepts with an integrated notch milling device allow for high flexibility in the complete machining of rolls and roll rings in a single set-up. Complete solution for Notching and marking steelwork rollers. Machines with maximum robustness and reliability. Modular Notching machines which can include measuring & marking. This versatility can optimise investment and save space at the workshop. Multifunction machine: corrugation milling module, marking system, measuring and centring module, bevelling function, standard soft corrugation cycles and option of customer specifications, and, if required, integration of complete roller lathing. Complex operations in a single setup. Easy machine handling soft interface, with automatic Notching and marking cycles. Includes the option of machining on tungsten carbide rings. Machine with maximum rigidity and excellent damping, even when it does not include lathing operations. Maximum precision and simplicity of use. Reduced preparation time thanks to the unique support bearing design built into the milling chuck. Robust milling head for different spindle diameters. Marking module with direct tools on special motor. Automatic withdrawal. Retractable measurement module, based on MARPOSS element, for on-site measurement and operational referencing. Ideal operational ergonomics and maximum safety. Software customizable to the customer’s needs. Popular across the emerging markets, DKD Ikjot United Rib cutting and name marking machines are ideal for fast growing steel companies aiming for higher productivity without compromising on the world-class ‘quality’. The solutions combine the rib cutting and name marking operation in a single machine and provide an unmatched competitive edge to the steel roll shops. Ideal for carbide rolls, the machines come with standard name marking device to perform dual operations. In addition to the features and advantages 4 axes CNC machine | 3 Axis simultaneous movement of CNC control system | User friendly software | Sturdy and rigid machine construction | Easy to operate CNC system | Better productivity and reduced operational expenditure | Improved pass life and avoids distortion of roll material and its properties | Enables faster change of branding with use of software Design Data: Many kinds of roll materials can be notched and marked easily, such as high Ni-Cr casing iron roll, H.S. steel roll and tungsten carbide roll ring. The main spindle body is made in cast iron, heat treated for stress relieving and artificial aging. This axis is driven by one A.C. synchronous motor in line with the spindle (without transmission) to avoid any backlash. Steel body Chuck: Dia. 500 mm, 11” ASA nose, complete with 4 independent Jaws. Only about 10 minutes requires notching for roll specification of DIA 340mm in DIA 340mm high Ni-Cr casting iron roll. CNC Control: CNC controller guaranteed quality, reliable long life quality and worldwide technical support at your area.

DKD Ikjot United | CNC Machines Building Division | A Preet Enterprises.

Ikjot United CNC Machines building facilities.

DKD Ikjot United is the one of the biggest CNC Machines Building Company, and is headquartered in New York, USA. It is a subsidiary of PREET and operates in 42 locations across 16 countries. DKD Ikjot United is the one of the largest PREET Enterprise with wide range of machine shop products like CNC Double column VMC, CNC Roll Lathes, CNC Mega Lathes, CNC Notching & Branding Machines, CNC VTL & CNC Special Purpose Machines (up to 20 axes). DKD Ikjot United CNC machine building is now placed among the most valuable CNC machine building brands worldwide. These technology sectors demand a high degree of precision, efficiency, and reliability – technical characteristics that are ensured by DKD IKJOT UNITED (IU) through an assembly that is defined down to the smallest detail, a high production depth and an unlimited desire to innovate. The machines are therefore energy-efficient and maintenance friendly and provide high quality — ideal conditions for the maximum use over many decades. Integrated into an owner-managed globally active group of companies with worldwide activities DKD Ikjot United ensures the flexibility which is necessary for customers in order to invest in production machines of this magnitude & which ensures a solid foundation for a long-term business partnership. Our responsible personnel contribute to this via our worldwide sales and service network. They continuously develop individual solutions in close cooperation with the customer, and in this way ensure an endless market-oriented, development & expansion. DKD Ikjot United Lathes are the result of experience in the manufacturing of machine tools combined with outstanding reliability and the application of state-of-the-art technologies. DKD Ikjot United offers heavy-duty turning lathes with working ranges with workpiece diameters of 3,000 mm and weights of 200 tons. Turning large workpieces is a highly demanding application for a machine tool. Along with highly precise processing, the focus is on sturdy design, reliability, and longevity of the machine. Producers of rotationally symmetrical workpieces, such as forges or roll manufacturers, achieve the highest efficiency with lathes by DKD Ikjot United The integration of milling heads, logo milling units or other optional equipment allows for the performance of very complex machining tasks in one single setup. With its NWD series, heavy-duty lathes with hydrostatic guidance systems, and the smaller lathes of the P series, DKD Ikjot United offers customized machines for the processing of, for example, section rolls, forged shafts, or rotors with a maximum of precision. DKD Ikjot United has also developed solutions for roll rings. The product range is complemented by the outstanding DKD Ikjot United service – comprehensive consulting from the earliest stages of a project, developing an application concept that is tailored to your needs and a broad range of after sales services.

DKD Ikjot United Equipment’s sectors: Forges & Foundries | Long Product Rolling Mills | Paper Industries | Roll Manufacturing | Steel Industries | Service Industries | Oil & Gas Industries | General Industries | Plastic Industries | Automobile Industries.

DKD Ikjot United Roll Shop Turnkey Solution.

From the individual roll shop equipment’s like CNC roll lathes, CNC roll notching & Branding Machines, CNC Roll Grinding Machines to a fully automated roll shops, DKD Ikjot United offers the complete line-up of possible choices. In close cooperation with you, DKD Ikjot United plans your roll shops and delivers them on a turnkey basis, if requested. Following a detailed analysis of your requirements, DKD Ikjot United experts develop a concept tailored to your machining capacities. DKD Ikjot United offers a comprehensive range of roll shop equipment to handle rolls, such as chock changing devices, chock tilters, roll transfer cars, loaders and much more. Each roll shop component is designed and manufactured entirely in-house at DKD Ikjot United By the help of the Roll Shop Management System, The following is an excerpt from the list of large steel companies we have been working with for many years. We propose a wide range of products and accessories to adapt to any need or problem, providing a customised, bespoke, unique solution: Fully aware that it is one of the most demanding lathing applications. Our main goal is to reduce processing times throughout the working life of the machine. In other words, maximum reliability over time and machine durability. Machines specifically designed for nip rollers, both at machine mechanical concept and programming levels. Operator interface suitable for the customer’s particular operations. Option of combined machines for operations involving lathing and Notching/marking rollers. 4-guide machines capable of operating with a wide range of rests, including hydrostatic rests for heavier workpieces. Solutions designed to carry out roughing and finishing operations in the same machine. Option of including milling modules for distance between faces in nip roller ends. Manufacturers of forging rollers and nip rollers achieve maximum productivity thanks to DKD IKJOT UNITED lathes. The range of solutions for the steel industry is rounded off with an efficient consultancy service, from the start of the project in order to ensure the machine is fully customised, through to an extensive after-sales service throughout the machine’s working life. The CNC Roll turning Lathe is the ultimate replacement solution for Manual Lathes used by Steel Plants in the Roll Shop for Roll machining and pass cutting. Available in various Models, the CNC roll turning lathes drive a huge improvement in productivity, reduce the need for labour, eliminate manual errors and reduce the space required for turning operation in machining the Rolls. The CNC Roll turning lathes from DKD Ikjot United provide an economical solution to improve the quality of end product, productivity of the manufacturing process and thus adds to your profitability. Machine Tools Features: High Torque capacity at Head stock Face plate | European Brand Zero backlash with ball screw & twin type of nut for long life | Higher cutting force | 4 Guide way Lathe Bed with LM Guides & Box Guide ways | S.S. Telescopic cover to protect LM / Box guideways.

Roll Branding Machine for Rebar Rolling Mills

Roll Notching Machines For Rebar Rolling Mills

CNC Notching & Branding Machine

CNC Roll Marking Machine

CNC Notching & Branding Machine for Rebar Rolling Mills

CNC Roll Notching & Branding Machines

CNC Roll Notching Machine

CNC Roll Branding Machine

CNC Roll Notching Machine

Roll Notching and Branding Machine

CNC Roll Notching and Branding Machine for Rebar Rolling Mill

Roll Notching and Branding Machine