Preet Brothers Limited | CNC Spare & Maintenance Division | CNC Spares Division | A Preet Enterprises

DKD Ikjot United provides an Extensive Training Program in Operation & Programming and Machine Maintenance for all the DKD Ikjot United Customers. This program represents a unique, phased approach of the training, combining hands-on training, and real world examples to empower customers with the skills needed to get the most out of their investment. DKD Ikjot United offers standard programming instructions all over the world. DKD Ikjot United Training Program offers both Basic training and advanced training for machine types, ranging from Standard Roll Turning to advanced Multi-Tasking Machines. This ensures an appropriate entry point for any individual, regardless of their current level of skill and expertise. The Operations and Programming training suits both the Operators and Engineers with the knowledge and skills to get the most out of our various control systems. The Maintenance Program covers both Mechanical and Electrical training to ensure your DKD Ikjot United machines run consistently at the highest performance and safety level. To ensure the usage & full proficiency of DKD Ikjot United machine tools, DKD Ikjot United recommend customers to enrol for the appropriate training courses. This will enable customers to effectively use the CNC the earliest possible after their machine is installed, When you purchase a DKD Ikjot United Machine you’re not only getting the most technologically advanced machine tool you can buy, but also you’re automatically enrolled in Optimum – a customer support program that is the hallmark of the industry. DKD Ikjot United’s commitment to our customers begins with availability of after sales support. You are never more than a phone call away from getting the help you need. Well Trained and experience DKD Ikjot United Service engineers are available to customer on phone- Toll free no. +15165909970 During business hours from 8am till 11pm. Problems related to machine operations and machine breakdown recovery process from power failure etc. are addressed and resolved over phone. No matter what the age of your DKD Ikjot United machine, you can be rest assured that replacement parts will be available at DKD Ikjot United part centres. From complete modular units like spindle assemblies to the simplest commercial parts, we maintain an inventory of parts from ball screws, linear guides, turret couplings, coolant & Hydraulic pumps, printed circuit boards, switchgears, motors, and spindle cartridges to the smallest non-critical items like fasteners and grease lubricants. We understand the high cost of downtime. That’s why our parts department operates Monday through Saturday, with same-day shipment for orders received. Spindle is the heart of any machine and is easily susceptible to damage due to accidents. Repair/replacement of the spindle can be expensive and time consuming affair. In order to support customers, DKD Ikjot United India has installed a spindle cartridge repair facility with advanced testing & condition monitoring equipment’s such as dynamic balancing machine, test JIG with simulators, vibration, temperature & lubrication monitoring devices. With the new facility spindle repairs can be carried out quickly and at affordable costs. DKD Ikjot United also offers Spindle exchange program which cuts downtime, provides the highest levels of quality, and reduces costs.

For Turnkey Solutions, DKD Ikjot United has established itself as a strong player in offering total turnkey solutions which include right from process selection to time study preparation to design and supply of tooling and fixtures to prove out at customers place. Turkey activities include:- Provide appropriate Engineering solutions for benefit of customer | Selection of most suitable machine & cycle time estimation by studying component drawing | Provide end to end Turn Key solution for component machining from various industries like Automobile, Medical, Wind power, Die & Mould, General Engineering, Pump Industry | Suggest most suitable & cost efficient process to improve Productivity, Quality & to reduce production cost | Provide total Fixture Designing Solutions. By our dedicated design team using 3D modelling CAD and FEA software | On-site Machine operating & Programming training | On-site support to customer for successful commissioning of machine | Arrange Training programs at Technology Centre to educate customer

Preet Brothers Limited has been serving steel industry for last four decades, Preet Brothers Limited is known for its versatile manufacturing capabilities by providing turnkey solution for Hot Rolling Mill | Long Product Rolling Mills projects with annual capacity up to 1,000,000 Tons | Flat Products Rolling Mill with annual capacity up to 3,000,000 Ton | CNC Roll Shop Equipment’s | PE Buildings | Over Head Cranes. Preet Brothers Limited Is The One Of The Largest Rolling Mill Building Company And Is Headquartered In New Delhi, India. It Is A Subsidiary Of Preet Group And Operates In 42 Locations Across 16 Countries. Preet employees over 2650 skilled people comprising of experienced engineers lead by a professional management.

DKD IKJOT UNITED | CNC MACHINE BUILDING DIVISION | A PREET ENTERPRISE.

DKD Ikjot United | CNC Machine Building Division | A Preet Enterprise is the one of the largest PREET Enterprise with wide range of machine shop products like CNC Double column Vertical Machining Centres (VMC), CNC Roll Turning Lathes, CNC Roll Lathes, CNC Notching & Branding Machines, CNC VTL & CNC Special Purpose Machines (up to 20 axes). DKD Ikjot United CNC machine building is now placed among the most valuable CNC machine building brands Worldwide. These technology sectors demand a high degree of precision, efficiency and reliability – technical characteristics that are ensured by DKD IKJOT UNITED (IU) through an assembly that is defined down to the smallest detail, a high production depth and an unlimited desire to innovate. The machines are therefore energy-efficient and maintenance friendly and provide high quality – ideal conditions for the maximum use over many decades. Integrated into an owner-managed globally active group of companies with worldwide activities DKD Ikjot United ensures the flexibility which is necessary for customers in order to invest in production machines of this magnitude & which ensures a solid foundation for a long-term business partnership. Our responsible personnel contribute to this via our Worldwide sales and service network. They continuously develop individual solutions in close co-operation with the customer, and in this way ensure an endless market-oriented, development & expansion. DKD Ikjot United Lathes are the result of experience in the manufacturing of machine tools combined with outstanding reliability and the application of state-of-the-art technologies. DKD Ikjot United offers Heavy – Duty Turning Lathes with working ranges with workpiece diameters of 3,000 mm and weights of 200 tons. Turning large workpieces is a highly demanding application for a machine tool. Along with highly precise processing, the focus is on sturdy design, reliability and longevity of the machine. Producers of rotationally symmetrical workpieces, such as forges or roll manufacturers, achieve the highest efficiency with lathes by DKD Ikjot United The integration of milling heads, logo milling units or other optional equipment allows for the performance of very complex machining tasks in one single setup. With its NWD series, heavy-duty lathes with hydrostatic guidance systems, and the smaller lathes of the P series, DKD Ikjot United offers customized machines for the processing of, for example, Section Rolls, Forged Shafts or Rotors with a maximum of precision. DKD Ikjot United has also developed solutions for roll rings. The product range is complemented by the outstanding DKD Ikjot United service – comprehensive consulting from the earliest stages of a project, developing an application concept that is tailored to your needs and a broad range of after sales services. DKD Ikjot United Equipment’s sectors: Forges & Foundries | Long Product Rolling Mills | Paper Industries | Roll Manufacturing | Steel Industries | Service Industries | Oil & Gas Industries | General Industries | Plastic Industries | Automobile Industries.

CNC Notching & Branding MAchine Spares

CNC Roll Lathe Spares

CNC Roll Shop Equipment Spares

Custom Built Parts for High Speed Rebar Rolling Mills

Custom Built Parts for Hot Strip Mill

Custom Built Spares in CNC Machine Shops

Equipment's for Narrow Hot Strip Mills

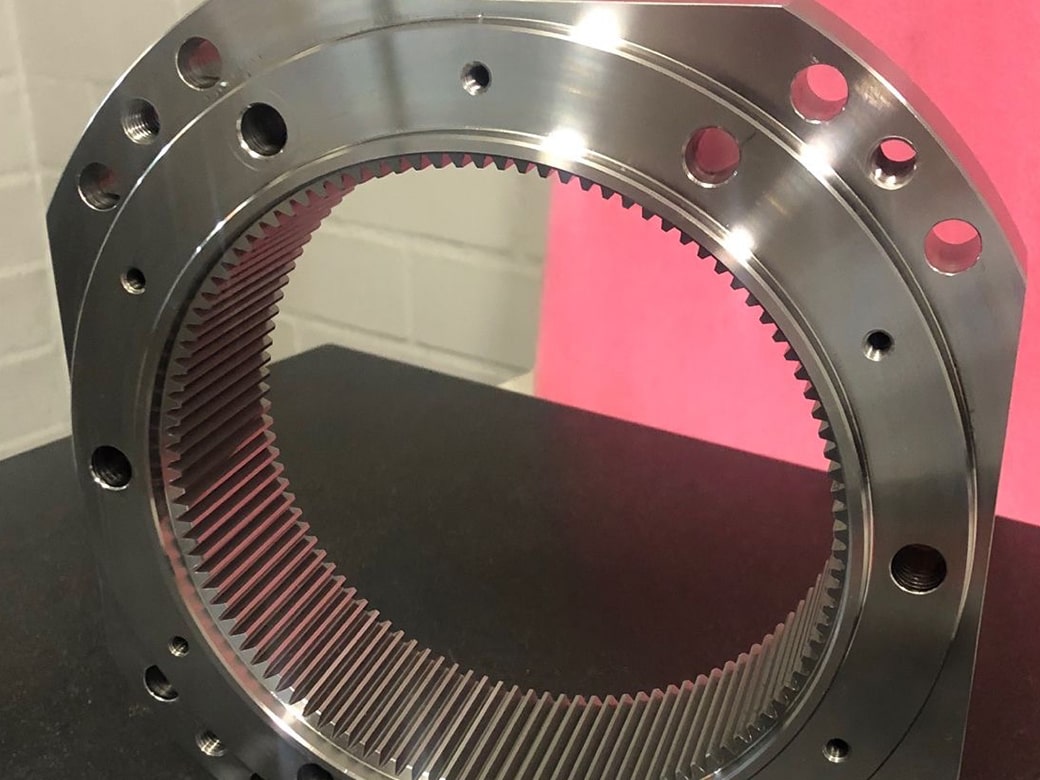

Hardend and Profile Gears for Hot Strip Mills

Parts for CNC Verticle Lathes

Rolls on CNC Roll Turning Lathes