SANJOG CRANES | OVERHEAD CRANE DIVISION | A PREET ENTERPRISE

OVERHEAD CRANE DIVISION

SANJOG Cranes | Crane Division | A Preet Enterprise Has Successfully Designed, Built And Executed Small, Medium And Mega Size Hoists | Overhead Cranes | Components For Cranes | Gantry Cranes | Jib Cranes | Transfer Carts | Cantilever Cranes | Other Types Of Lifting Elements. The Bridge cranes (also referred to as Overhead cranes) are cranes with a lifting system like hoist or open winch. If you need an overhead crane that increases productivity, enhances safety and helps minimize your maintenance costs, look to SANJOG Cranes & Components, one of top crane manufacturer. We design and manufacture a full range of standardized and custom engineered overhead cranes and crane kits that are relied on by crane builders and end-users in multiple industries, in multiple applications and in more than 70 countries on five continents. Overhead cranes from SANJOG Cranes & Components come in two styles, box girder and standard profile, and feature an integrated lifting mechanism, typically a hoist or open winch. Our optimized combination of crane structure and lifting mechanism (whether for lifting, cross travel or long travel) reduces hook approaches and maximizes the useful area of your facility. Hoists come in under running, top running, foot mount and built-up designs. End Trucks are available in top running, top running bogey and underhung types. Overhead Cranes from 500 kg to 400 ton Standardized Construction Versatile modular design Adaptable to multiple applications Highly reliable components Robot Welded Maximum strength Highest quality Uniform welds Better use of space with our bridge cranes. The optimized combination of structures and mechanisms (lifting, cross travel and long travel) on these cranes reduce hook approaches and that maximize the useful areas. Construction of structural welded elements, done with automated and robotic systems, which guarantee the repeatability of welding processes and high product quality. Steel making is a continuous process. The melt shop is a hazardous environment of extreme heat, choking dust, hot metal and naked flame. Melt shop cranes must be able to lift and carry buckets of liquid metal safely. Making molten steel The ingredients for steel come from two main sources: raw materials and scrap. Because they are different substances, they are treated separately. Iron ore and coking coal are combined in a direct reduction process to produce solid metallic iron. A ladle crane lifts the melted iron for mixing with scrap to create molten steel. The scrap coming from the scrapyard is loaded in the furnace with an overhead charging crane. The main hoisting machinery lifts the bucket to the furnace for melting. An auxiliary hoist on the crane opens and closes the bucket during loading. Depending on the facilities, a basic oxygen furnace or an electric arc furnace could be used. In a full-size mill, the scrap is added to iron, but in a Preet mini mills, the scrap might be the only raw source of liquid metal. Casting into shape From the initial furnace blast in the steel creation process, a teeming crane helps to mix the molten metal in the right proportions. Once the mix is right, liquid steel is then cast into shape. Tundish cranes are typically utilized in tundish maintenance and handling. Multi-function cranes The charging crane, ladle crane, teeming crane, and tundish crane are all quite similar and can be defined by their location and function in the plant. They are usually overhead traveling cranes that are fitted with special attachments to lift the giant ladles that contain liquid metal. They often perform more than one function and are used as backup for each other. Auxiliary hoists can be attached for scrap charging and maintenance functions, such as cleaning the empty ladles or lifting the furnace shell. Up for the challenge Every SANJOG Cranes hot metal crane is designed specifically for the unique challenges of this environment. Increased working coefficients, a differential gear reducer, redundancy in all critical systems, a backup brake on the rope drum, and motion limiters are just some of the technologies we employ. Automation of repetitive movements and an air-conditioned, ergonomic cabin keep the driver comfortable and able to concentrate on the task at hand. Keep your crane healthy To help the cranes last, exposed areas are protected against heat and dust. Our cranes can be fitted with remote monitoring so you can follow the operating statistics of the crane throughout its lifecycle. Routine maintenance helps to prevent unexpected faults, minimize downtime and maximize the productivity of the crane.

SANJOG PEB | PE BUILDING DIVISION | A PREET ENTERPRISE.

SANJOG PEB | PE Building Division | A Preet Enterprise Building Systems is one of the largest pre-engineered steel building (PEB) companies in the world and is a 100% subsidiary of Preet and multi-billion dollar business conglomerate Industries, one of the largest privately-owned companies in India. Its product list consists of pre-engineered steel buildings (PEB) applicable for factories, warehouses, metro rails, supermarkets, aircraft hangars, sports stadiums, auditoriums, etc. Other products include structural steel, sandwich panels, storage solutions, Sanjog Roof (SR), Sanjog Wall (SW), Sanjog Deep Decking Panel and Sanjog Standing Seam Panel (SSS-600). Sanjog offers one of the most comprehensive Pre-engineered steel buildings-PEB product portfolios globally, with applications in major market segments including heavy industry, infrastructure, high-rise buildings, warehouses, factories, oil and gas and leisure structures. The company maintains a strong reputation for delivering customer- designed and cost- effective solutions for steel buildings that are manufactured to the highest quality standards, and a commitment to providing top class service to its customers. Our commitment to excellence provides unmatched product quality, coupled with speed, safety and superior sales services. We at SANJOG PEB | PE Building Division | A Preet Enterprise offer a worry-free solution to our clients. We go that extra-mile through our systems, process and our internal orientation to ensure that commissioning a Sanjog project is a seamless and effortless experience for our clients. Pre-engineered steel buildings (PEB) are a steel structures built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascia’s, canopies, crane systems, insulation etc., based on the customer’s requirements. All the steel buildings are custom designed to be lighter in weight and high in strength. Thus steel building designs have become more flexible, durable and adaptable over the last four decades which has made steel one of the preferred materials for building construction. PEB’s are ideal for non-residential and wide-span low-rise buildings. Some of the key advantages of PEB include economical in cost, factory controlled quality, durability, longevity, flexibility in expansion, environmentally friendly, faster installation, etc. Pre-engineered steel buildings are used for diverse applications such as factories, warehouses, showrooms, supermarkets, aircraft hangars, metro stations, offices, shopping malls, schools, hospitals, community buildings and many more. As a leading PEB manufacturer, SANJOG PEB provides the complete service of engineering, fabrication and erection thus ensuring better quality control at every stage of the process. Pre-engineered steel buildings consists of following components: Primary Members / Main Frames | Secondary Members / Cold Formed Members | Roof & Wall Panels | Accessories, Buyouts, Crane System, Mezzanine System, Insulation, etc. | Sandwich Panels.

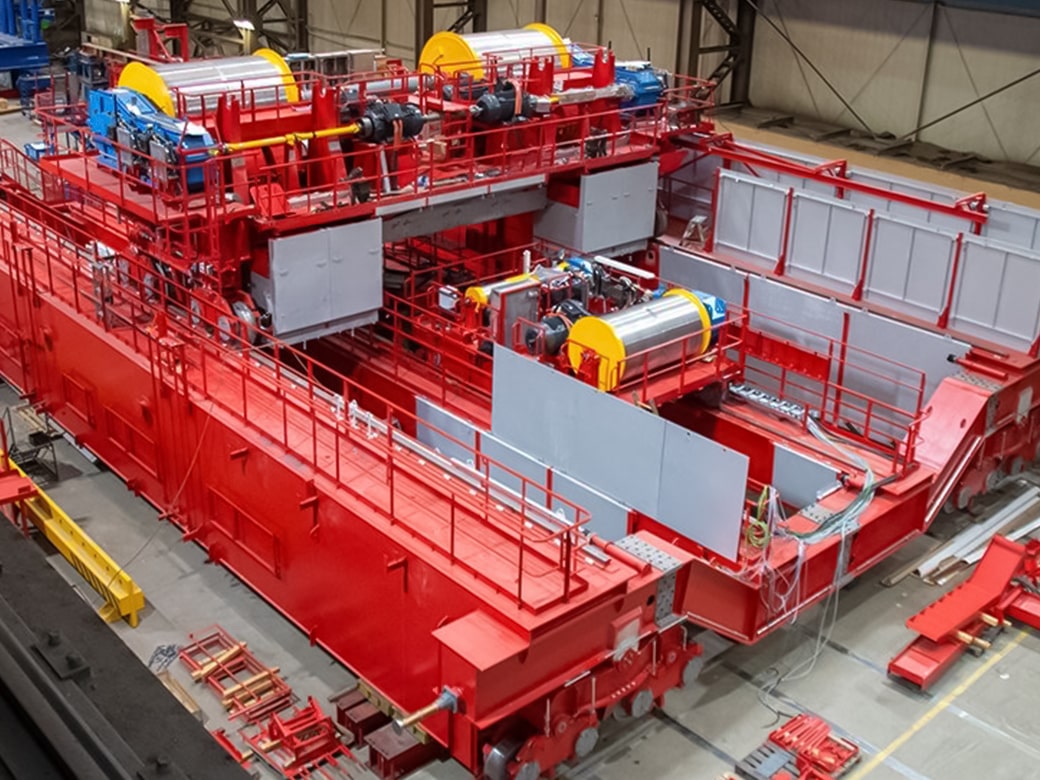

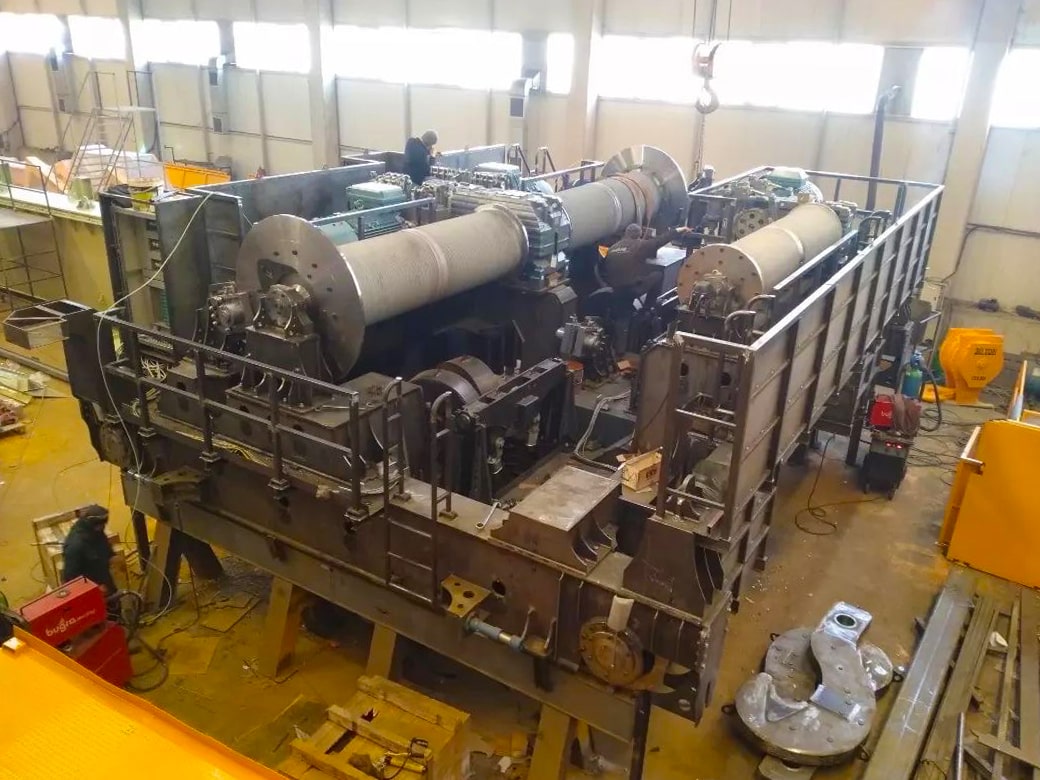

350 Ton x 25 Ton Overhead Crane for Steel Melt Shops

450 Ton x 35 Ton Overhead Crane for Steel Melt Shops

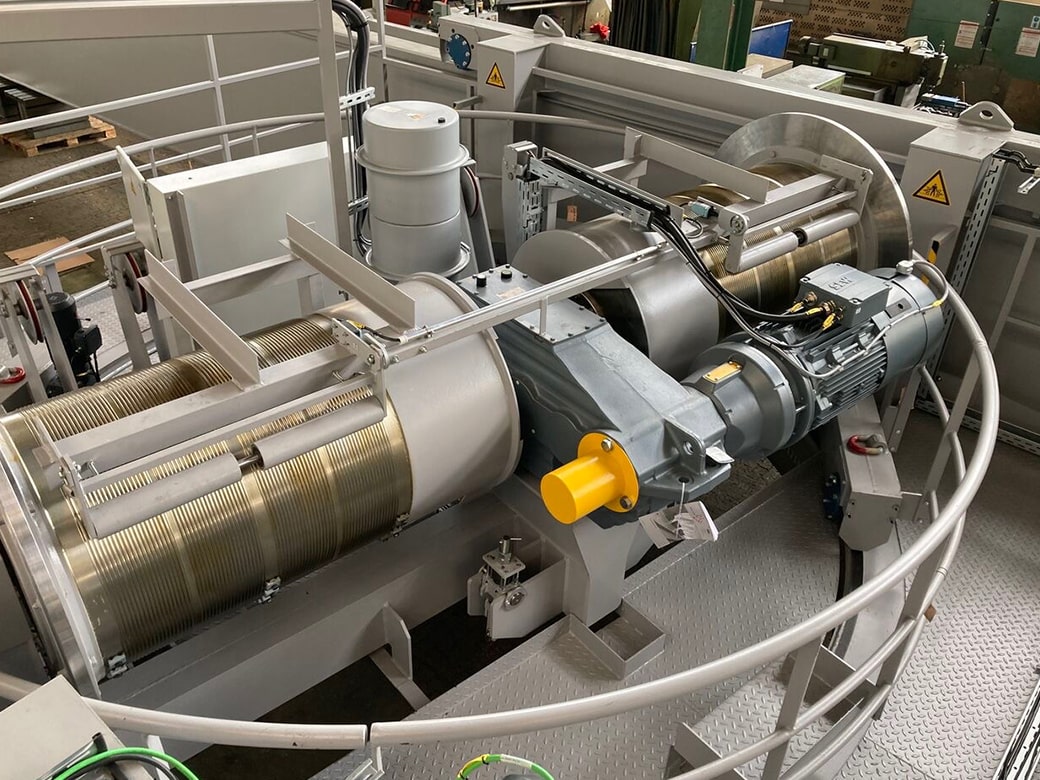

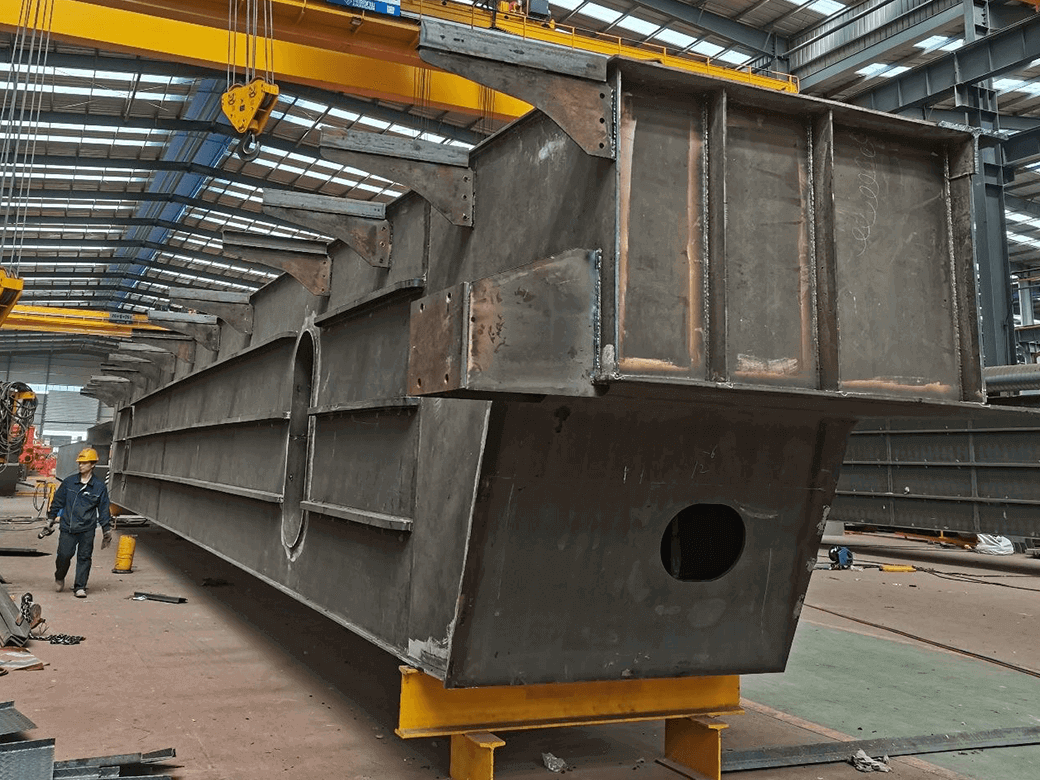

Crane Manufacturing Site at Sanjog

Crap for Overhead Cranes

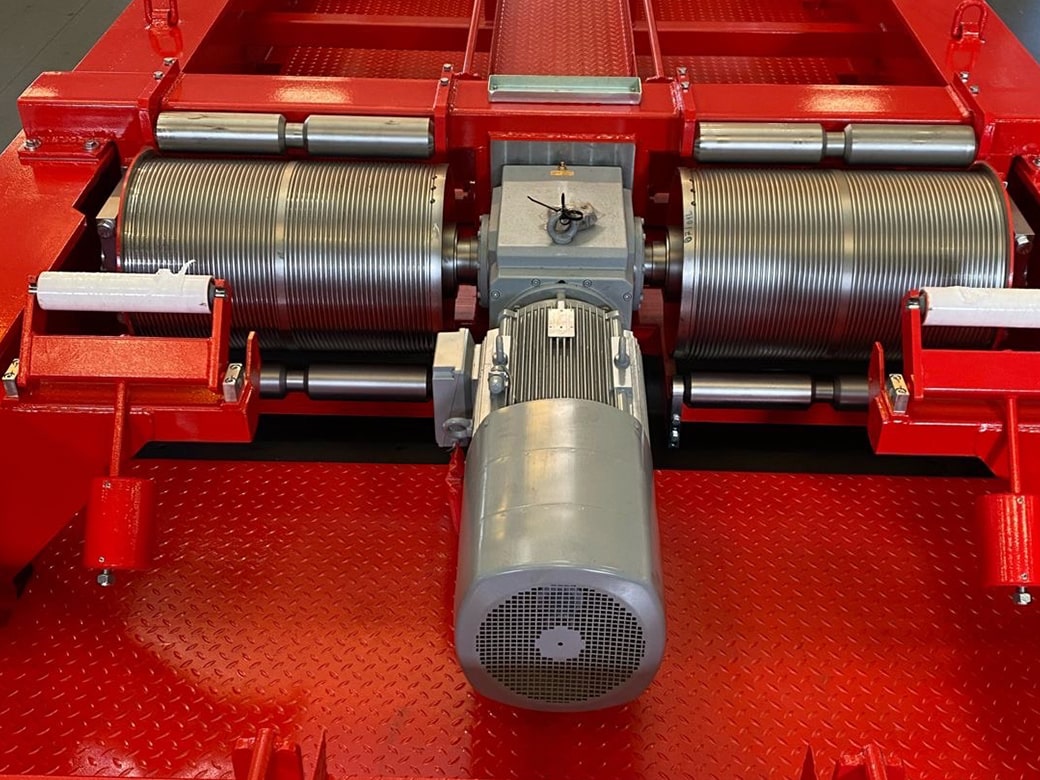

Overhead Crane Assembly Shop at Sanjog

Overhead Crane Assembly Shop at Sanjog

Overhead Cranes for Forging Industry

Overhead Cranes for Heavy Engineering Shops

Overhead Cranes for Hot Strip Rolling Mills

Overhead Cranes for Liquid Material Handeling in Steel Melt Shop

Overhead Cranes for Rolling Mills and Steel Melt Shops

Overhead Cranes for Steel Industries

Overhead Cranes

Overhead Cranes

Heavy Overhead Crane Manufacturing Bay at Sanjog

Heavy Overhead Cranes for Steel Melt Shops

Liquid Material Handling Cranes for Steel Melt Shops

Open Yard Cranes

Robotic Welders at Overhead Crane Manufacturing Site

Laddle Car for Steel Melt Shop

Special Cranes for Custom Built Application