Preet Brothers Limited | Wire Rod Rolling Mills: PREET Wire Rod Block Mill Max. Speed 90 Meter Per Second | A Preet Enterprises

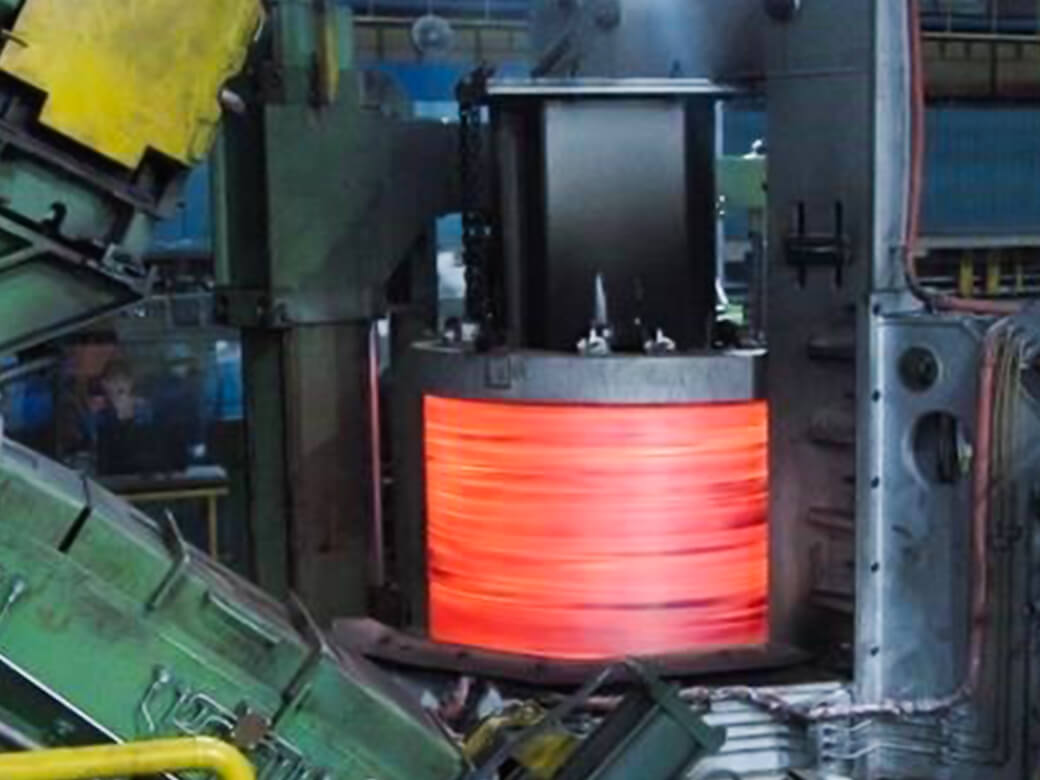

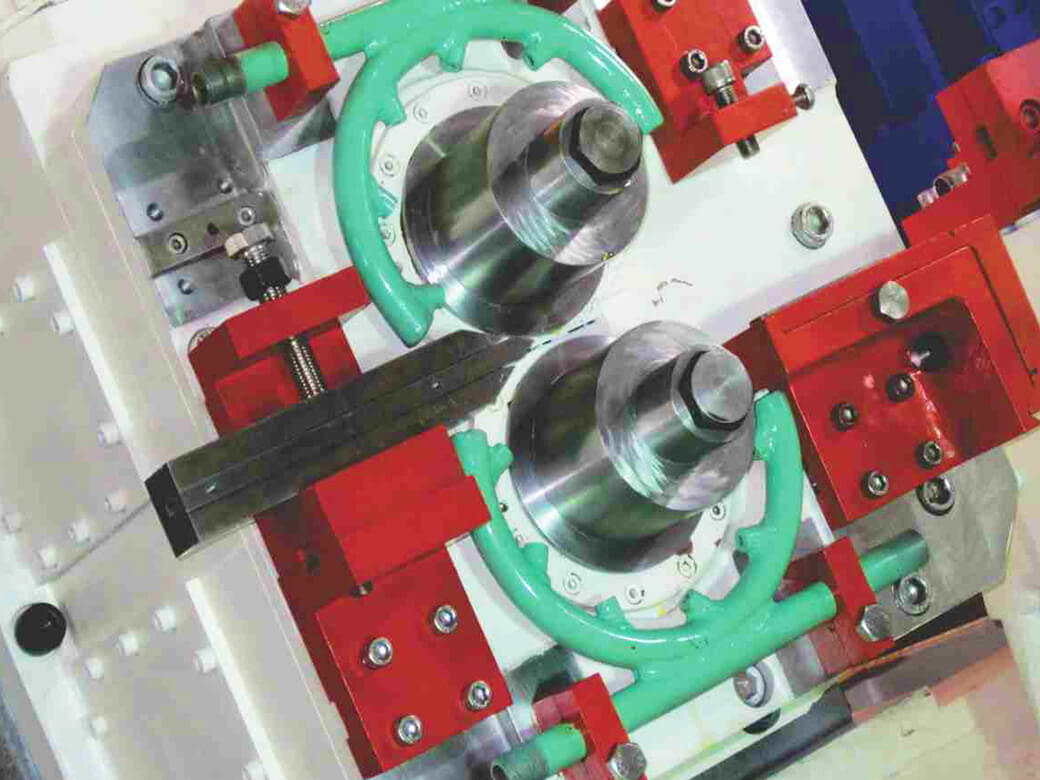

Delta/ V type high speed rolling block. Ideally suited for Stainless and Special Steels with 18 % average reduction. Ring size 175 – 155 mm for finishing stands. and 215 – 195 mm for pre finishing stands. Identical Roll units on both sides, enables operators to keep a min. stock of spare roll units. Heavy-duty design with low pass height. Ensures greater stability & negligible vibration levels at high speeds. The 45 degree, ultra-high speed/high precision block is used for rolling demanding steel grades or for production of alloy steel, stainless steel, low & high carbon steel grades at high rate, both coiled through wire rod lines. The reliable operating speeds of this block can reach 90 meters per second, with a design speed of 110 meters per second. The block mill, generally used for production of concrete reinforcement grades at a high rate, in straight condition and delivered onto cooling bed, reliably achieves operating parameters. In this last case, the use of the finishing block in combination with the Preet High-Speed Delivery System for the production of straight bars on cooling bed, besides higher productivity, close tolerances and excellent surface on final product, allows the total number of stands in the finishing mill to be minimized. All passes in the blocks come in V arrangement (45° inclined to the vertical).

PREET BROTHERS LIMITED | LONG PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE

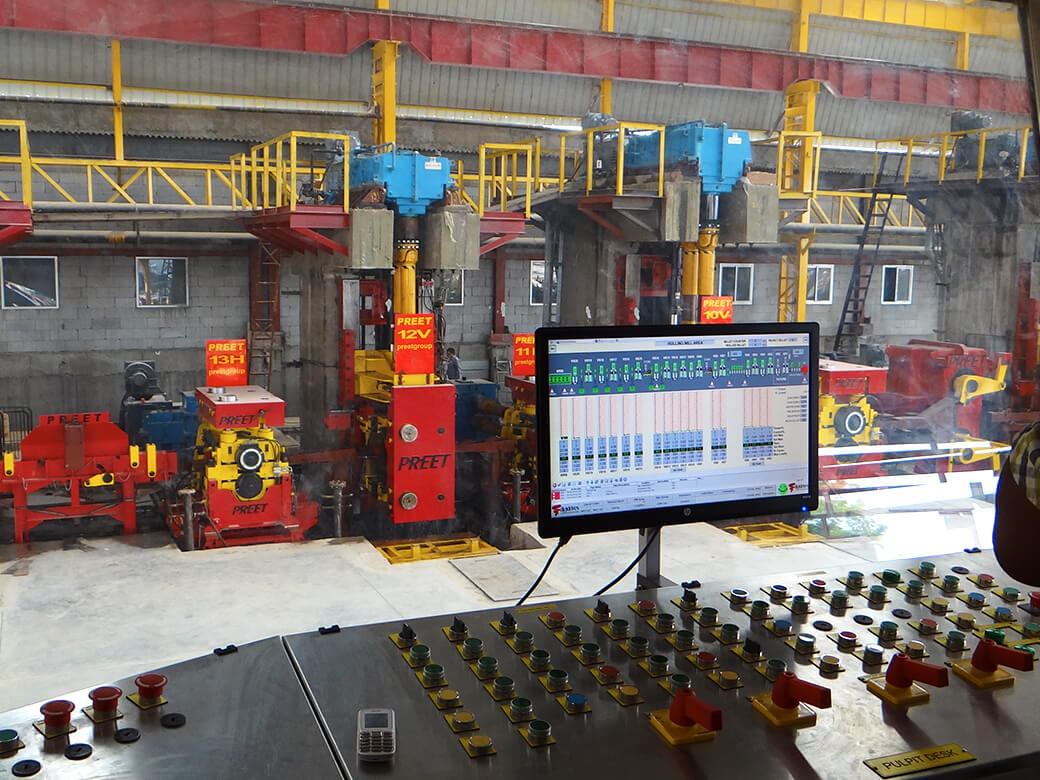

Preet Brothers Limited | Long Product Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects with annual capacity up to 1,000,000 Tons like: Rebar Rolling Mills, Wire Rod Rolling Mills, Bar Rolling Mills, Light Section Rolling Mills, Medium Section Rolling Mills, Heavy Section Rolling Mills. Besides complete plants Preet Brothers Limited | Long Product Hot Rolling Mill Division also under-take custom built design equipment’s based on the latest technology for various rolling mill equipment and systems like Rebar Rolling Mills | SBQ Rolling Mills | Wire Rod & Bar Rolling Mills | Small Section Rolling Mills | Medium Section Rolling Mills | Heavy Section Rolling Mills On Turnkey Bases (EPC & EP&S). Reheating Furnaces for Rolling Mills | Housingless stands for Hot Rolling Mills | Convertible Housingless Stands for Hot Rolling Mills | Universal Housingless Stands for Section Rolling Mills | Cantilever Stands for Hot Rolling Mills | Wirerod Mono-Block for Hot Rolling Mills | Sizing Mills for Hot Rolling Mills | Crank Shears for Hot Rolling Mills | Flying Shears for Hot Rolling Mills | Crop & Cobble Shears for Hot Rolling Mills | Crank cum Flying Dividing shears for Hot Rolling Mills | Thermo-processing units (TMT Plants) for Hot Rolling Mills | Harden Ground Gears & Gear boxes & Profile Ground Gears & Gear boxes | Entry and Exit Roller Guides Harden & Profile Ground Gears & Gear boxes | Slitting Guide boxes for 2 / 3 / 4 / 5 / 6 slitting Harden & Profile Ground Gears & Gear boxes | Sliding apron (Braking Slide) Rake type Cooling beds Harden & Profile Ground Gears & Gear boxes | Cold Shears of various sizes (150-1500Tons) | Dispatch & Bundling systems | Bar counters | Magnetic Stackers for Section handling | Single / Multi Groove Straighteners for on-line & off-line application in section rolling mill | Hot Saws & Cold Saws for Section Rolling Mill | Roll Changing Robots & Tilters for Rebar Rolling Mills | Preet Brothers Limited Roll-pass designs for slitting, angles, channels, I-beams & H-beams. Latest technology and high productivity of our plants: Guided by these concepts, we supply a complete scope of any green-field rolling mill for long products, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. Technical department @Preet Brothers Limited, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

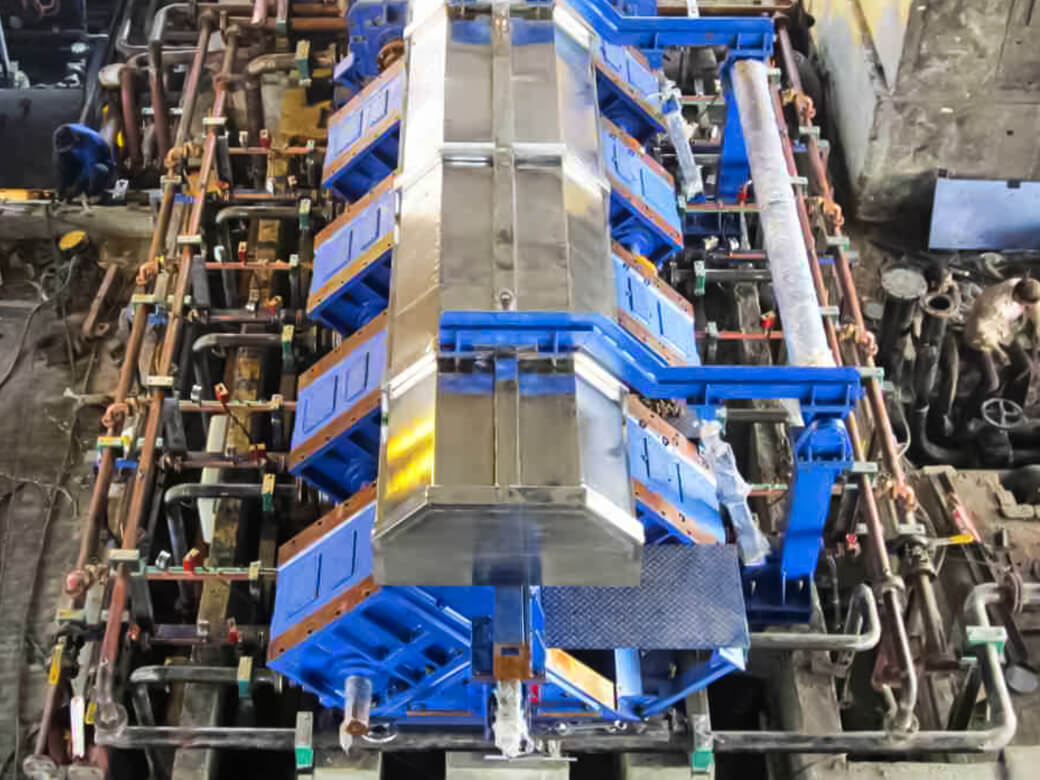

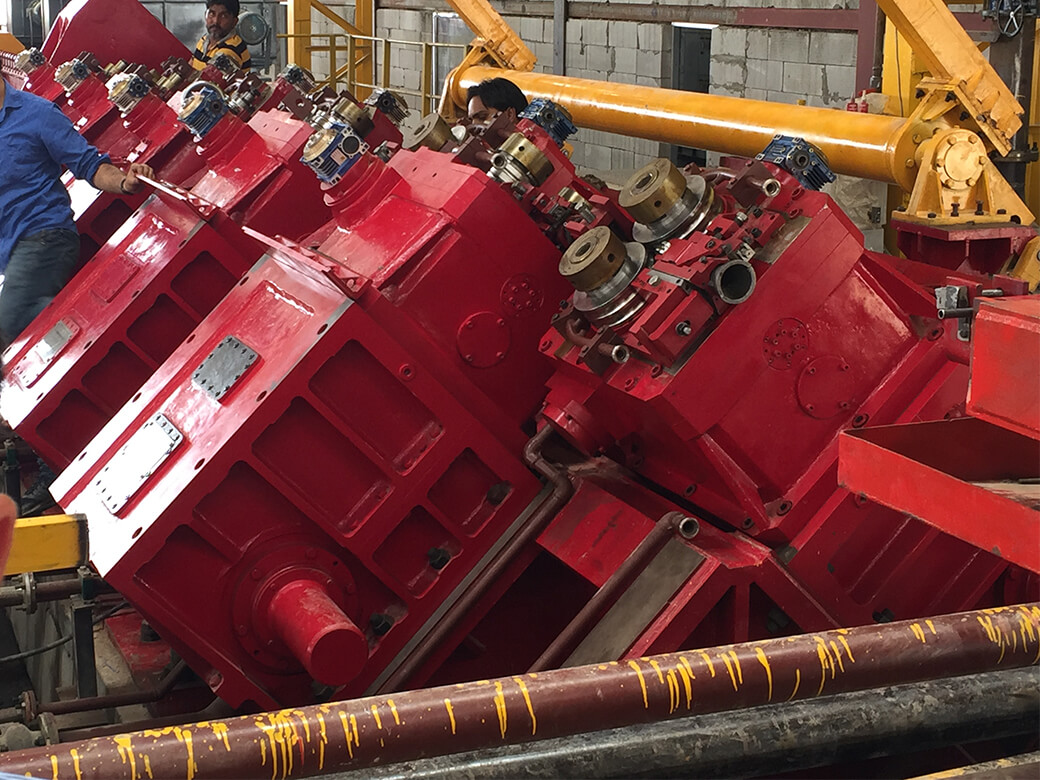

8 Stand Wire Rod Rolling Mill Block

10 Stand Wire Rod Rolling Mill Block

block mill stand under assembly for Wire Rod Rolling Mill

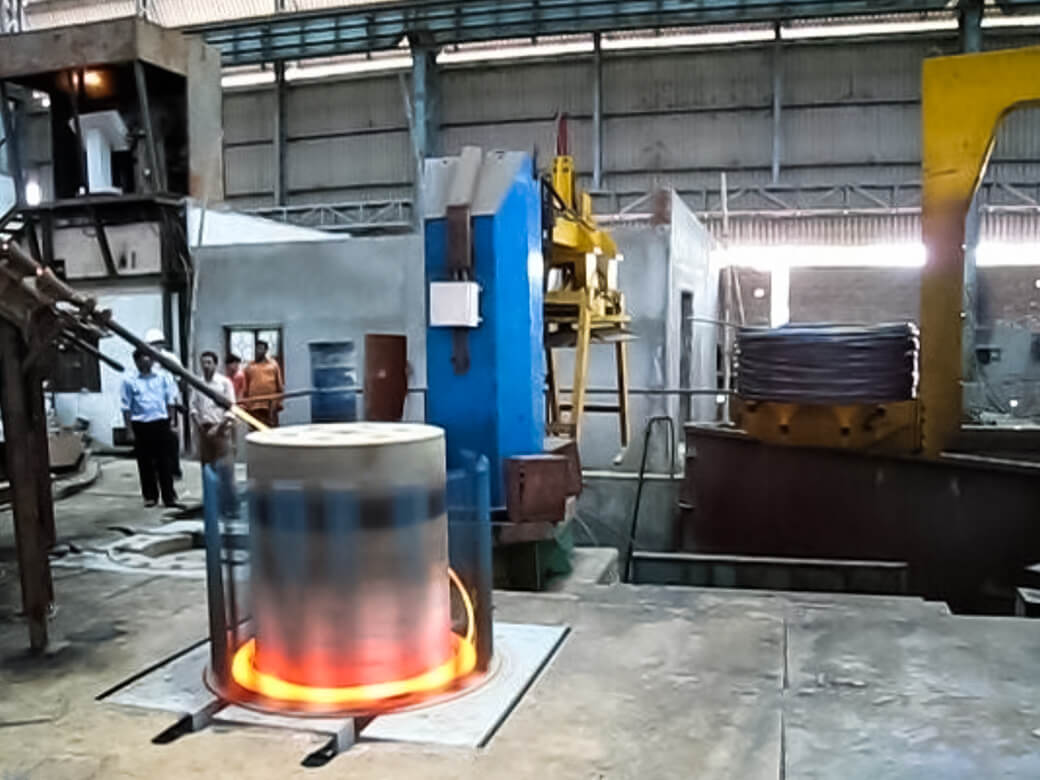

Coil Compactor for Wire Rod Rolling Mill

Garret Coiler for Bar & Rod Rolling Mills

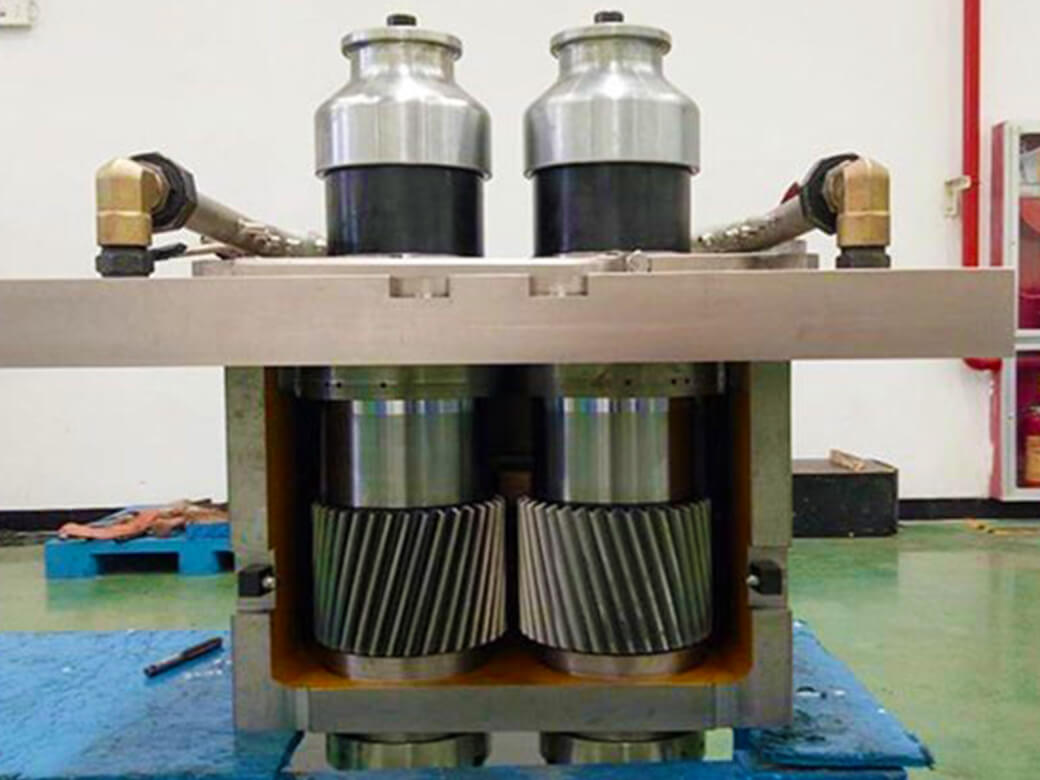

Gear Assembly for Wire Rod Rolling Mill Block Stand

H/V Wirerod Rolling Mill

Continuous Wire Rod Rolling MIlls

Intermediate Stands for Wire Rod Rolling Mill

Laying Head for Wire Rod Rolling Mill

Stand for Wire Rod Rolling Mills

Wire Rod Rolling Mill

Wire Rod Rolling Mills