DKD Ikjot United | CNC Roll Grinding Machines | CNC TC Ring & TC Roll Grinding Machines | A Preet Enterprises.

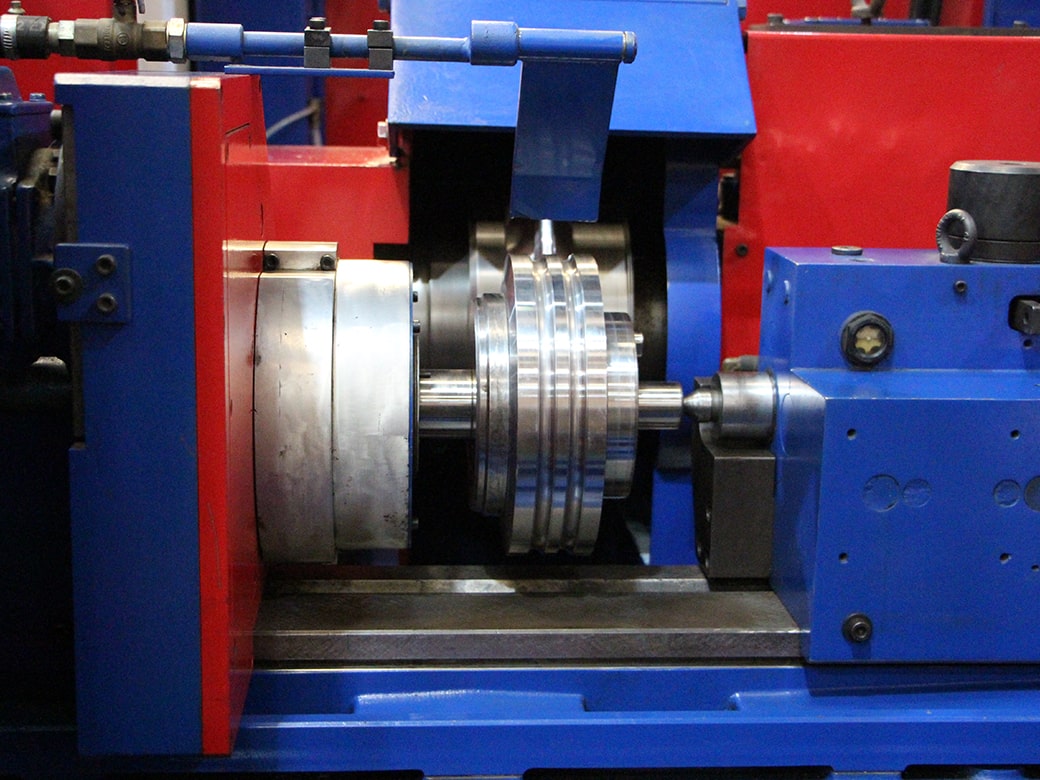

DKD Ikjot United Tungsten Carbide Roll Grinder For grinding outer diameter and pass profile of Tungsten Carbide Rolls & total grinding solution for Ring Grinding shop.

Applications: External & Plunge Grinding of pass profiles on Tungsten Carbide Ring. Features Powered by Siemens Controls | Regrinding of TC Rings | Guide Rolls | Custom-built grinding cycle

CNC Ring Grinding Machine Standard Features & Description of Machine

Standard features & description of machine (key features & description of the machine) Ring grinding machine which can accommodate tungsten carbide ring and entry guide rolls grinding with three axis CNC and driven by CNC controls. The special feature of this machine is the modular design concept incorporating rigid, multi-piece grey cast iron base housing all units such as grinding wheel head, work head, in feed slide and oscillation slide assembly. The solid construction provides rigidity for the machine during grinding. Base is made of FG 260 graded casting, stress relieved and provided with ribbings and rugged in construction to avoid any vibration resulting in better dampening effect. All slides and housing are made up of FG-260 graded cast iron. All castings are stress relieved. Guide way seating areas are scraped very accurately to have a good contact for the Guide way system. Fitted with linear motion guide ways of rigid linear rail and carriage block for the wheel head in feed axis Centralized lubrication for linear bearings and ball screw assembly. Preloaded ball screw of Grade C3 for both linear axes. Oscillation axis is with Turcite lined and with recirculation type of lubrication. Oscillation axis is driven with a preloaded ball screw grade C3. The grinding wheel spindle is driven with an AC induction motor. Wheel spindle is suitable for the front nose of taper 1:6. Work head spindle is driven by AC servo motor and of variable speed. Work spindle front nose is of standard A2-8 design. Manually operated expansion arrangement for work holding. Precise positioning of grooves of pass profiles with linear scale interface for the table axis. Provision of grinding cycles for plunge grinding and deep grinding. Coolant filtration system is offered with Centrifuge. Work room enclosure with top cover to take care of the grinding mist in the operational area.

DKD Ikjot United | CNC Machines Building Division | A Preet Enterprises.

Ikjot United CNC Machines building facilities.

DKD Ikjot United is the one of the biggest CNC Machines Building Company, and is headquartered in New York, USA. It is a subsidiary of PREET and operates in 42 locations across 16 countries. DKD Ikjot United is the one of the largest PREET Enterprise with wide range of machine shop products like CNC Double column VMC, CNC Roll Lathes, CNC Mega Lathes, CNC Notching & Branding Machines, CNC VTL & CNC Special Purpose Machines (up to 20 axes). DKD Ikjot United CNC machine building is now placed among the most valuable CNC machine building brands worldwide. These technology sectors demand a high degree of precision, efficiency, and reliability – technical characteristics that are ensured by DKD IKJOT UNITED (IU) through an assembly that is defined down to the smallest detail, a high production depth and an unlimited desire to innovate. The machines are therefore energy-efficient and maintenance friendly and provide high quality — ideal conditions for the maximum use over many decades. Integrated into an owner-managed globally active group of companies with worldwide activities DKD Ikjot United ensures the flexibility which is necessary for customers in order to invest in production machines of this magnitude & which ensures a solid foundation for a long-term business partnership. Our responsible personnel contribute to this via our worldwide sales and service network. They continuously develop individual solutions in close cooperation with the customer, and in this way ensure an endless market-oriented, development & expansion. DKD Ikjot United Lathes are the result of experience in the manufacturing of machine tools combined with outstanding reliability and the application of state-of-the-art technologies. DKD Ikjot United offers heavy-duty turning lathes with working ranges with workpiece diameters of 3,000 mm and weights of 200 tons. Turning large workpieces is a highly demanding application for a machine tool. Along with highly precise processing, the focus is on sturdy design, reliability, and longevity of the machine. Producers of rotationally symmetrical workpieces, such as forges or roll manufacturers, achieve the highest efficiency with lathes by DKD Ikjot United The integration of milling heads, logo milling units or other optional equipment allows for the performance of very complex machining tasks in one single setup. With its NWD series, heavy-duty lathes with hydrostatic guidance systems, and the smaller lathes of the P series, DKD Ikjot United offers customized machines for the processing of, for example, section rolls, forged shafts, or rotors with a maximum of precision. DKD Ikjot United has also developed solutions for roll rings. The product range is complemented by the outstanding DKD Ikjot United service – comprehensive consulting from the earliest stages of a project, developing an application concept that is tailored to your needs and a broad range of after sales services.

DKD Ikjot United Equipment’s sectors: Forges & Foundries | Long Product Rolling Mills | Paper Industries | Roll Manufacturing | Steel Industries | Service Industries | Oil & Gas Industries | General Industries | Plastic Industries | Automobile Industries.

DKD Ikjot United Roll Shop Turnkey Solution.

From the individual roll shop equipment’s like CNC roll lathes, CNC roll notching & Branding Machines, CNC Roll Grinding Machines to a fully automated roll shops, DKD Ikjot United offers the complete line-up of possible choices. In close cooperation with you, DKD Ikjot United plans your roll shops and delivers them on a turnkey basis, if requested. Following a detailed analysis of your requirements, DKD Ikjot United experts develop a concept tailored to your machining capacities. DKD Ikjot United offers a comprehensive range of roll shop equipment to handle rolls, such as chock changing devices, chock tilters, roll transfer cars, loaders and much more. Each roll shop component is designed and manufactured entirely in-house at DKD Ikjot United By the help of the Roll Shop Management System, The following is an excerpt from the list of large steel companies we have been working with for many years. We propose a wide range of products and accessories to adapt to any need or problem, providing a customised, bespoke, unique solution: Fully aware that it is one of the most demanding lathing applications. Our main goal is to reduce processing times throughout the working life of the machine. In other words, maximum reliability over time and machine durability. Machines specifically designed for nip rollers, both at machine mechanical concept and programming levels. Operator interface suitable for the customer’s particular operations. Option of combined machines for operations involving lathing and Notching/marking rollers. 4-guide machines capable of operating with a wide range of rests, including hydrostatic rests for heavier workpieces. Solutions designed to carry out roughing and finishing operations in the same machine. Option of including milling modules for distance between faces in nip roller ends. Manufacturers of forging rollers and nip rollers achieve maximum productivity thanks to DKD IKJOT UNITED lathes. The range of solutions for the steel industry is rounded off with an efficient consultancy service, from the start of the project in order to ensure the machine is fully customised, through to an extensive after-sales service throughout the machine’s working life. The CNC Roll turning Lathe is the ultimate replacement solution for Manual Lathes used by Steel Plants in the Roll Shop for Roll machining and pass cutting. Available in various Models, the CNC roll turning lathes drive a huge improvement in productivity, reduce the need for labour, eliminate manual errors and reduce the space required for turning operation in machining the Rolls. The CNC Roll turning lathes from DKD Ikjot United provide an economical solution to improve the quality of end product, productivity of the manufacturing process and thus adds to your profitability. Machine Tools Features: High Torque capacity at Head stock Face plate | European Brand Zero backlash with ball screw & twin type of nut for long life | Higher cutting force | 4 Guide way Lathe Bed with LM Guides & Box Guide ways | S.S. Telescopic cover to protect LM / Box guideways.

CNC Roll Grinders for Wire Rod Rolling Mills

CNC Roll Grinding Machine for Wire Rod Rolling Mill

CNC Roll Grinding Machines

CNC Roll Grinding Machines