Preet Brothers Limited | Harden & Profile Ground Gears & Gear Boxes | A Preet Enterprises

Preet Has a Successful History in The Design and Manufacturing of a Wide Range of Worm | Parallel Shaft | Helical & Spiral Bevel Helical Gears with Horizontal & Vertical

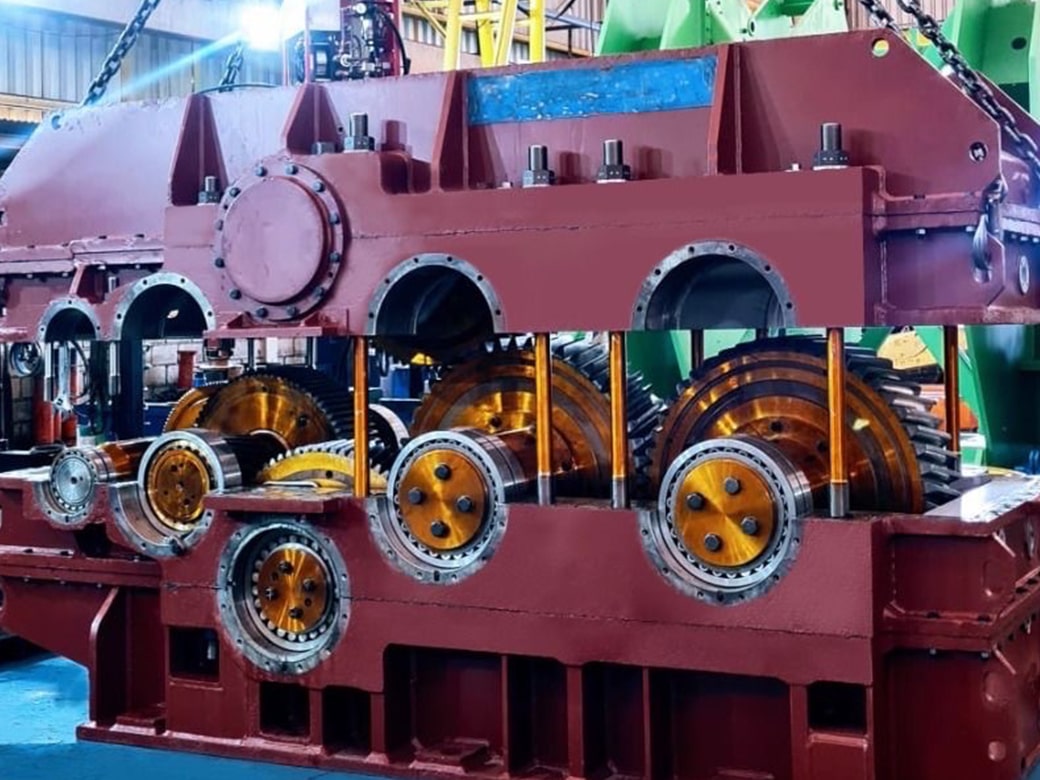

Output Shafts In Various Sizes. Preet’s Helical Gear Boxes, Especially, Have Won the Approval of Industrial Plants All Over Globe. They Are Compact and Light, Thereby Saving Space, Reducing Foundation Structure Costs and Lubricating Oil Consumption. Preet Gear Boxes Are Specially Designed to Operate at Optimum Efficiency Wherever They Have Been Installed – Whether in Power Stations, For Material Handling Systems in Coal & Lignite Mines | Cement Plants | Steel Rolling Mills | Fertilizer Plants | Sugar Plants | Chemical Plants | Plastic Industries | Textile Industry | Ports. Preet Has Unmatched Expertise in Providing Custom- Made Gearboxes for Steel Rolling Mills | High Speed Turbine | Sugar Mills | Marine Applications | Plastic Extrusions | Cement Mills | Rubber Mills | Hydro Turbine | Windmill Gearboxes. Ample Proof of Preet’s Unsurpassed Range Is Evidenced in Their Specialized Gear Boxes for Cooling Towers in Power Plants, Telecommand Antenna Drives and Satellites for The Indian Space Program, Naval Vessels as Well As A Variety Of Gear Drive Units For Steel Plant Applications. Today, Preet’s Expertise in Providing Custom Gear Boxes Has Become an Integral Facet of Its Value-Added Customer Service. Preet’s Gears & Gear Boxes (Power Transmission Product) Range Includes Worm Gears | Helical Gears | Fluid , Geared & Flexible Couplings | Planetary Bucket Wheel Gearbox | Special Gears Including Gear Drive For Seven Roll Stands In Tube Mill Plant | Sheet Metal Un-Coiler Gearbox | Gear Drive For Piercing Milling Seamless Tube Plant | Mill Gearbox In Seamless Tube Plant | Gears & Gear Boxes For Briquetting Mill In Continuous Steel Plant For Hot Strip Mill | 330kw Wind Mill Gears & Gear Boxes | Gears & Gear Boxes For Sponge Iron Kiln | Marine Gearbox For Advanced Offshore Patrol Vessel Propulsion. Preet’s Product Range Of Almost All Types Of Bulk Material Handling Equipment And Products To Choose From, Preet Has Today Expanded Its Production To Cater To Diverse Material Handling Requirements Of Multiple Industries Including Steel | Power | Marine | Chemical | Cement | Coal And Wide Range Of Products Like Belt Conveyors | Idlers And Pulleys | Elevators And Chain Conveyors | Stackers | Reclaimers | Stacker-Cum-Reclaimers | Barrel Type Blender Reclaimers | Bridge Type Bucket Wheel Reclaimer | Wagon Tipplers And Beetle Marshalling Equipment | Side Arm Chargers & Pusher Car | Ship Loader And Unloaders | Crawler And Rail Mounted Trippers | Wagon Loaders | Crawler Mounted Bucket Wheel Excavator | Spreader | Mobile & Transfer Conveyors And Other Surface Mining Equipment | Specialized Shift Able Conveyors For Open Cast Mines | Drive Heads And Long Distance Conveyors | Salt Scraper And Scraper Reclaimer | Cable Reeling Drum | Apron Feeders | Paddle Feeders | Vibrating Feeders And Reciprocating Feeders | Roller Screen | Grizzly Feeders | Bin Vibrators | Impactors | Ring Granulators | Double/Single Roll Crushers | Hammer Mill Crushers | Rotary Breakers | Transfer Cars | Wind Turbine Generators. Preet’s Gear Division is acknowledged in the industry as the most modern in the country. All machineries and testing equipment’s are computer controlled, ensuring a high degree of precision in the manufacture and testing of gear components to DIN / AGMA international specifications. Preet is one of the very few companies to deploy the 3 Axis Co-ordinate Measuring Machine. Apart from a large concentration of Computerized Numerically Controlled (CNC) Machines, Preet has sophisticated gear profile testing machines, full-fledged testing/calibrating lab and Vacuum Spectrometers to check chemical analysis of raw material. Besides, there are flexible machining systems, a battery of state-of-the-art, quality control equipment, online computerized inventory control, production planning and execution programmes managed using state of the art ERP software. Deploying modern technology through CAD / CAM in engineering and manufacture on a continuous basis is a thrust area at Preet.

Custom Built Gearboxes: Preet’s Gear Division is largest Industrial Gear Manufacturer of innovative gearboxes, its related services and able to satisfy Power transmission needs in various industries. In addition to our wide product range, we offer customized Industrial gearboxes, made to order. With over four decades of market leadership, one of our major strengths is the ability to customize an existing standard product into a new design to meet customer’s particular specifications and reverse engineering. When requirements are of challenging nature, our highly trained engineering team strives to develop an optimized, tailor-made product to a specific application in close co-operation with the customer to suit their needs. Our experienced and qualified engineers secure that the product fulfils the requirements of even the most challenging and demanding applications. Successes and experience gathered from numerous deliveries to the process industry help us to assure the highest available trouble-free operation of gearboxes from standard catalogue range to tailor-made options. We are geared for managing new challenges with the most sophisticated technology, ultra-modern amenities, and most potential skilled labor to cater to your engineering industry needs. REFURBISH GEARBOXES: Preet undertakes refurbishment of any make, size and capacity of Industrial Gearboxes and Wind-mill Gearboxes with sophisticated infrastructure and through high precision equipment. with the commitment to deliver the highest quality of refurbished Gearboxes by recognizing root cause that prevents downtime of machines and any other criticalities, hence enhancing the Gearbox life span. GEARBOX REPAIR: Preet provide onsite repair services and assistance by evaluating all leading Gearbox’s health through endoscopic, effective, and efficient monitoring systems. ABOUT PREET Gears and Gear Boxes division SERVICES AT CENTERS: Walk in with your ailing gearbox and walk away with completely refurbished gearbox | Refurbished to near original (with latest advancements) for desired gearbox performance | Each and every component of your gearbox is scanned under our state of the art testing facilities for materials, tooth geometry/profile, etc. | Thorough analysis of failures with comprehensive and appropriate solutions by our experienced team of Design, Manufacturing, Quality and Service engineers | The most effective way of restoring the health of your Gear drives | Gearbox Re-engineering and development for any applications ON-SITE SERVICE SUPPORT: Pre- inspection at site of existing drives | Assessment and preparation of pre-inspection report | Collection of operating data for analysis | Availability of spares and requirements. ABOUT PREET Gears and Gear Boxes SERVICE & SUPPORT – MATERIAL HANDLING EQUIPMENT: Services – Driven by Customer Needs | Preet Gear and Gear Box Division Engineering offers service and support for bulk material handling equipment for industries in Mining | Cement | Power Generation | Fertilizer & Ports. ABOUT PREET Gears and Gear Boxes division SUPPORT INFRASTRUCTURE & ENGINEERS: Preet Machines Limited is the one of the biggest Rolling mills Building Company and is headquartered in New Delhi (INDIA). It is a subsidiary of PREET and operates in 102 locations across 46 countries. A network of trained and experienced service engineers are available for proactive support. Fully supported with engineering expertise from Preet offices. A dedicated Customer Care manufacturing facility catering to spares for material handling solutions for closer engineering support and better delivery timelines.

SERVICES PORTFOLIO

• Break Down / Field Services: Engineers on call | Rapid manufacture of critical parts to achieve minimum downtime | Maintenance Training | Start-up and Commissioning Assistance

• Spares Supply: Original / OEM parts Supply | Manufacture OEM spares through reverse engineering | Replacement of major parts and overhauling of equipment on flat cost basis

• Services for Existing or Used Equipment: Design Modifications | Relocate / Refurbish Equipment | Equipment Modernization | Capacity Enhancements

• Maintenance Contracts: Preet takes Annual Maintenance Contract | Need based Service Contract | Custom Maintenance Contract

QUALITY POLICY

CUSTOMER SATISFACTION: PREET – Gear Division has achieved ISO 9001 in November 1994 for quality management system. Achieved IMS ISO 9001:2015. It means our customers have complete assurance that PREET operates to the highest quality standards and that all regulatory requirements are met for our products and services while we continually strive to maintain and improve these standards that set us apart. Customer satisfaction has always been a fundamental part of our business but implementing IMS (Integrated Management System) standards ensures we identify all present customer needs and identify and assess future requirements. It also helps us to measure client satisfaction and enables us to continually improve our processes. An Integrated Management System can benefit our organization through increased efficiency and effectiveness, and cost reductions while minimizing the disruption caused by several external audits. It also shows our commitment to increased performance, employee and customer satisfaction, and continuous improvement. Preet Has A Successful History In The Design And Manufacture Of A Wide Range Of Worm | Parallel Shaft | Helical & Spiral Bevel Helical Gears With Horizontal & Vertical Output Shafts In Various Sizes. Preet’s Helical Gear Boxes, Especially, Have Won The Approval Of Industrial Plants All Over Globe. They Are Compact And Light, Thereby Saving Space, Reducing Foundation Structure Costs And Lubricating Oil Consumption. Preet Gear Boxes Are Specially Designed To Operate At Optimum Efficiency Wherever They Have Been Installed – Whether In Power Stations, For Material Handling Systems In Coal & Lignite Mines | Cement Plants | Steel Rolling Mills | Fertilizer Plants | Sugar Plants | Chemical Plants | Plastic Industries | Textile Industry | Ports. Preet Has Unmatched Expertise In Providing Custom- Made Gearboxes For Steel Rolling Mills | High Speed Turbine | Sugar Mills | Marine Applications | Plastic Extrusions | Cement Mills | Rubber Mills | Hydro Turbine | Windmill Gearboxes. Ample Proof Of Preet’s Unsurpassed Range Is Evidenced In Their Specialized Gear Boxes For Cooling Towers In Power Plants, Telecommand Antenna Drives And Satellites For The Indian Space Programme, Naval Vessels As Well As A Variety Of Gear Drive Units For Steel Plant Applications. Today, Preet’s Expertise In Providing Custom Gear Boxes Has Become An Integral Facet Of Its Value Added Customer Service.

2 Speed Type Hardend and Ground Gear Boxes

2hi Pinion Gear Box for Blooming Mill

Bevel Helical Gear Boxes

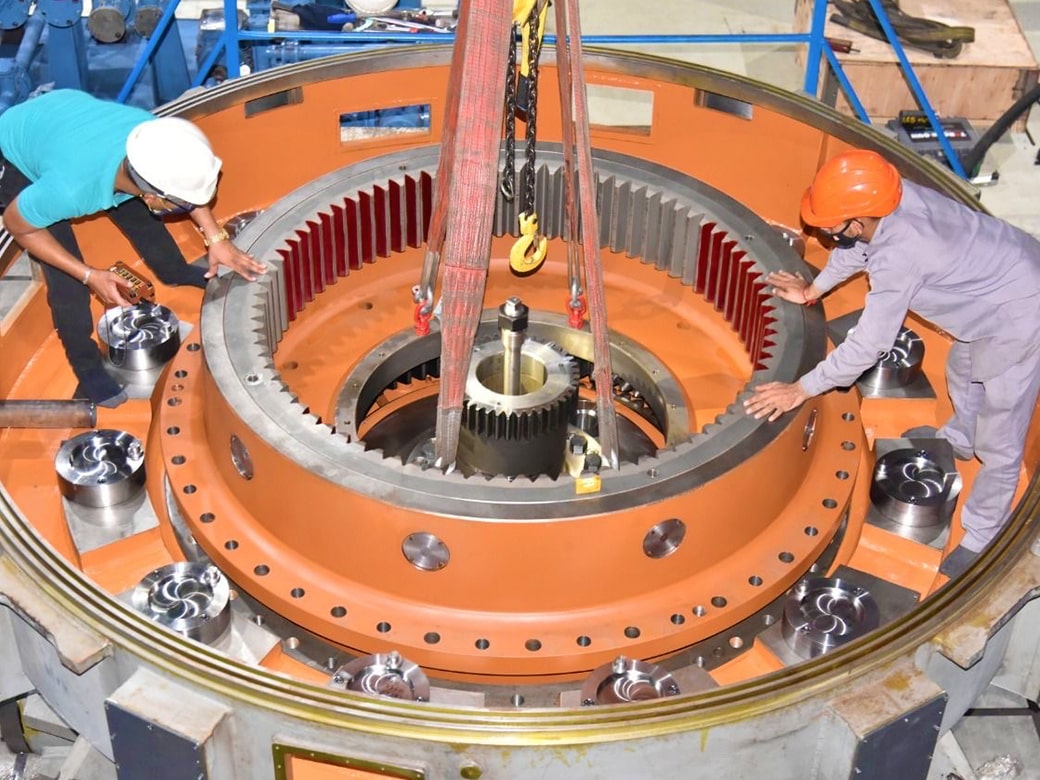

Bull Gears

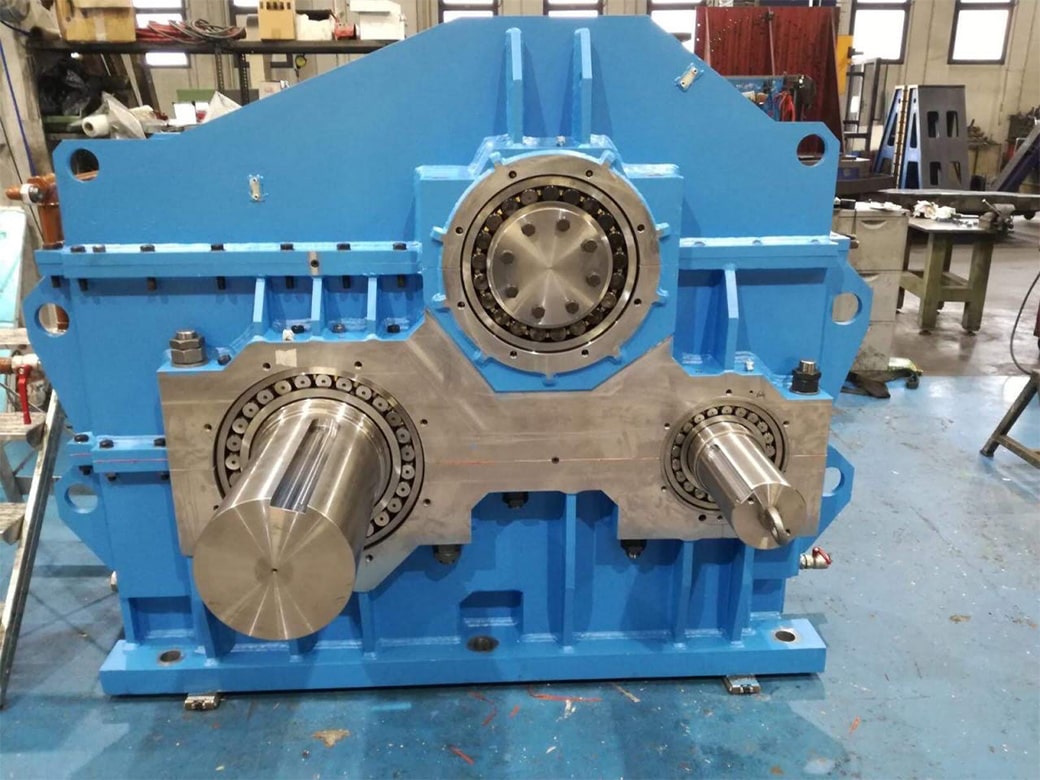

Cusotm Built Gear Box

Custom Built Gear Boxes

Custom Built Gear Boxes

Custom Gear Boxes

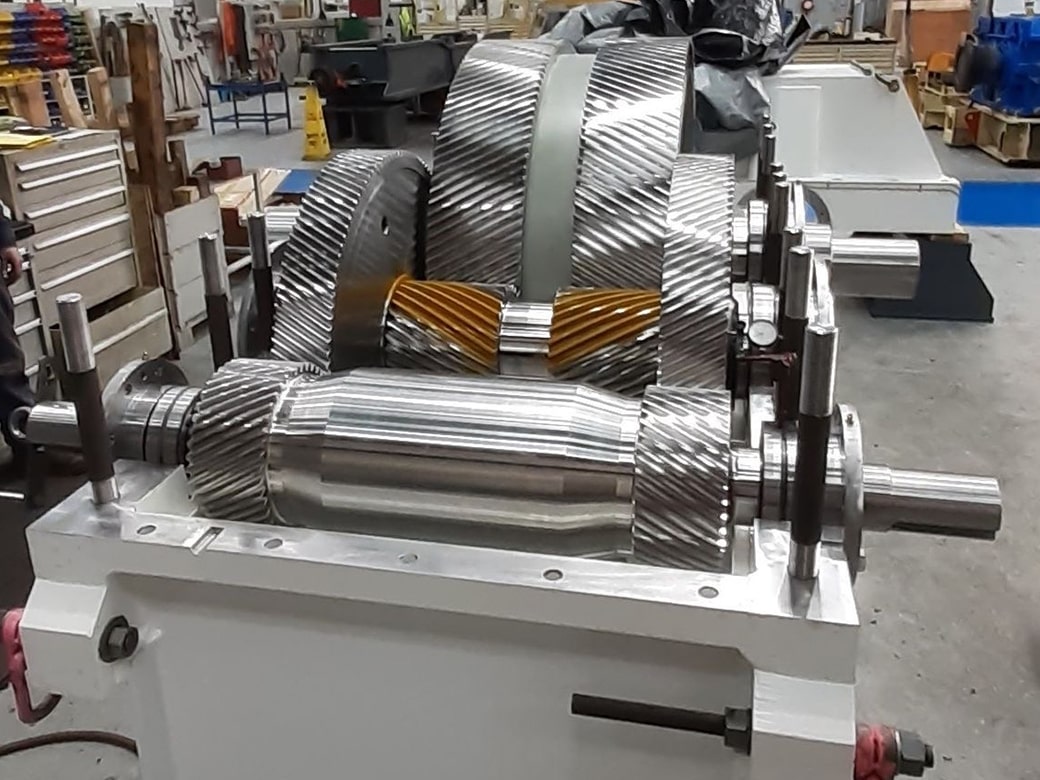

Double Helical Ground Gears

Double Helical Hardend and Ground Gear Boxes

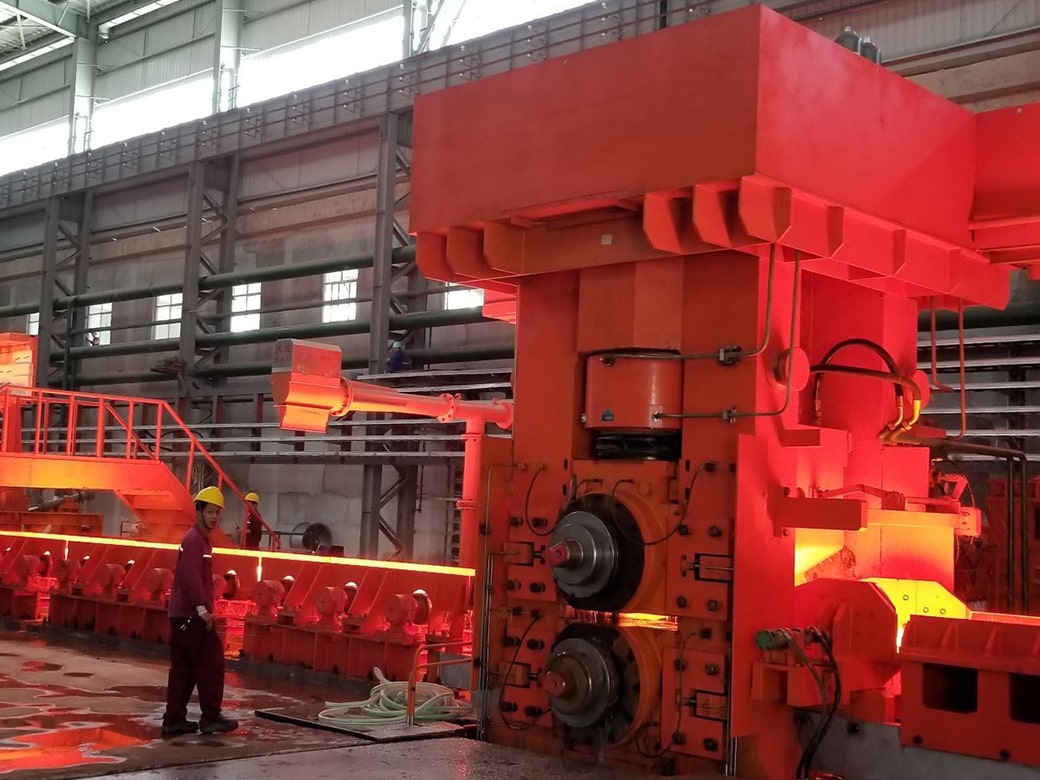

Gear Boxes for Rolling Mills

Gear Grinding Shop at PREET

Gear Grinding Shop

Grinding Shop at PREET

Hardend and Ground Gear Box for Rolling Mill

Hardend and Ground Gear Boxes

Heavy Duty Gear Boxes

Heavy Gear Boxes

Helical Gear Box for AOD

PREET Floor Shop

Reduction cum Pinion Gear Box for Vertical Stands for Rolling Mills

Reduction cum Pinion Gear Boxes for Rolling Mills