Preet Brothers Limited | Spare & Maintenance Division | Long Product Rolling Mills Spares Division | A Preet Enterprises

Long Product Rolling Mill Spare Division

Preet that engineers and constructs high-tech rolling mill plants needs to constantly analyze and optimize its own production system. That’s why we have systematically designed efficient processes in all our manufacturing facilities. All our manufacturing plants that have significantly cut component lead times which can better synchronize work processes and reduce transport as well as storage periods. We are equipped with all world class latest CNC machines like turning and milling center, CNC floor type boring machine, HMC, CNC VTL, CNC Gear Hobing Machines, CNC Gear Grinders and many more. A real added value because a customer can look forward to shorter delivery times. The plant is installed in our mechanical workshop where we can machine unit weights of up to 150 tons. What adds to the efficiency of Preet manufacturing facility is the close interaction between engineering and production team? A strong Preet Team of 950 employees work on a total area of 400,000 ton produce the core components of rolling mill technology, from fabricated/ welded structures to mechanically manufactured parts. Strong Team PREET consist of 1490 workforce all over the globe comprising of skilled workers and engineers led by a professional management. This winsome combination of expertise and resources has made the company an ideal turnkey solution provider for Flat and Long product Rolling Mill industry. It has a huge manufacturing setup spread over 950,000 of covered area. The entire production at Preet Group Machines is organized under four individual manufacturing units equipped with modern machines. Steel Rolling Mill Stands like Housing Less Rolling Mill Stands, Pre-Stress Rolling Mill Stands, Universal Rolling Housing Less Mill Stands for Section Rolling Mill / Structure Rolling Mill, Horizontal and Vertical Rolling Mill Stands (H/V Type), AOD converter Shop & LD Converter Shop. EOT Cranes up to 100 tons capacity. Shearing machines like start and stop type flying shears, continuous type flying shear, crank type flying shears, crop and coble shears, cold shears, billet cutting shear for M.S and S.S. Gear Couplings for all applications. Allied equipment for steel rolling mill like automatic cooling beds (Rack Type cooling beds), turn-over cooling beds, Section and bar straightening machines, TMT quenching boxes, twin channels, and hot/cold rolling mill for ferrous and non-ferrous metals. Complete range of Guiding equipment like entry guide boxes, twist pipes and slitting boxes (Slit Guide Box) Fabrication, Machining, and assembly up to 100 tons in single piece as per customer design and specifications. All the units deploy streamlined process systems that adhere to global standards of highest quality and safety.

SERVICE

Modernization and Retrofit, The area of retrofit and service is a very important field, especially in the segment of rebar rolling mills & section Rolling Mills. When purchasing a new rebar rolling mills & section Rolling Mills not only the cost of the machine but also the costs of “periphery” have to be considered (foundation, media connection …).With a retrofit, the customer saves this expenditure and receives a machine as good as new for lower costs, which fits into his existing layout and meets the current technical requirements. Retrofit: Our retrofit includes the worldwide retrofit and overhauling of machine tools and components for machine tools, independent of make and machining processes. For this, not only the obligatory Preet assembly team, but also the capacities of purchasing, production and quality assurance, electrical commissioning and documentation are available. Service: In the field of service, we offer you a worldwide service regarding all aspects of machine tools. This service is independent of manufacturer or machine type and includes everything from erection, alignment, commissioning, trouble shooting, repair, and test machining to customer-specific requirements. Our service supports you with machine tools and machine tool components – worldwide, independent of make and machining processes. Beside service in the event of “damage”, we also offer you preventive measures for avoiding machine breakdowns / downtimes e.g. due to service / maintenance contracts. These have to be adjusted and adapted to the individual customer. Spare part service: By manufacturing of high-precision machine tools, that are tailored to specific customer requirements, we adapted to it when it is about material procurement and storage capacity. To be able to provide our global customers with spare parts quickly, essential wear parts are kept in store for customer orders and on-site service. Furthermore, we have established a worldwide network of suppliers and reliable forwarding and courier service companies. Thus, we can fulfil your requests at any place and at any time, in desired quality and quantity. We offer you also additional machining of your parts as well as manufacturing of new parts in our job order production. We will support you if questions or problems with your old machines arise. We can come back to our in-house archive, where documents of old machines from the last 40 years are kept.

Preet Brothers Limited has been serving steel industry for last four decades, Preet Brothers Limited is known for its versatile manufacturing capabilities by providing turnkey solution for Hot Rolling Mill | Long Product Rolling Mills projects with annual capacity up to 1,000,000 Tons | Flat Products Rolling Mill with annual capacity up to 3,000,000 Ton | CNC Roll Shop Equipment’s | PE Buildings | Over Head Cranes. Preet Brothers Limited Is The One Of The Largest Rolling Mill Building Company And Is Headquartered In New Delhi, India. It Is A Subsidiary Of Preet Group And Operates In 42 Locations Across 16 Countries. Preet employees over 2650 skilled people comprising of experienced engineers lead by a professional management.

PREET BROTHERS LIMITED | LONG PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE:

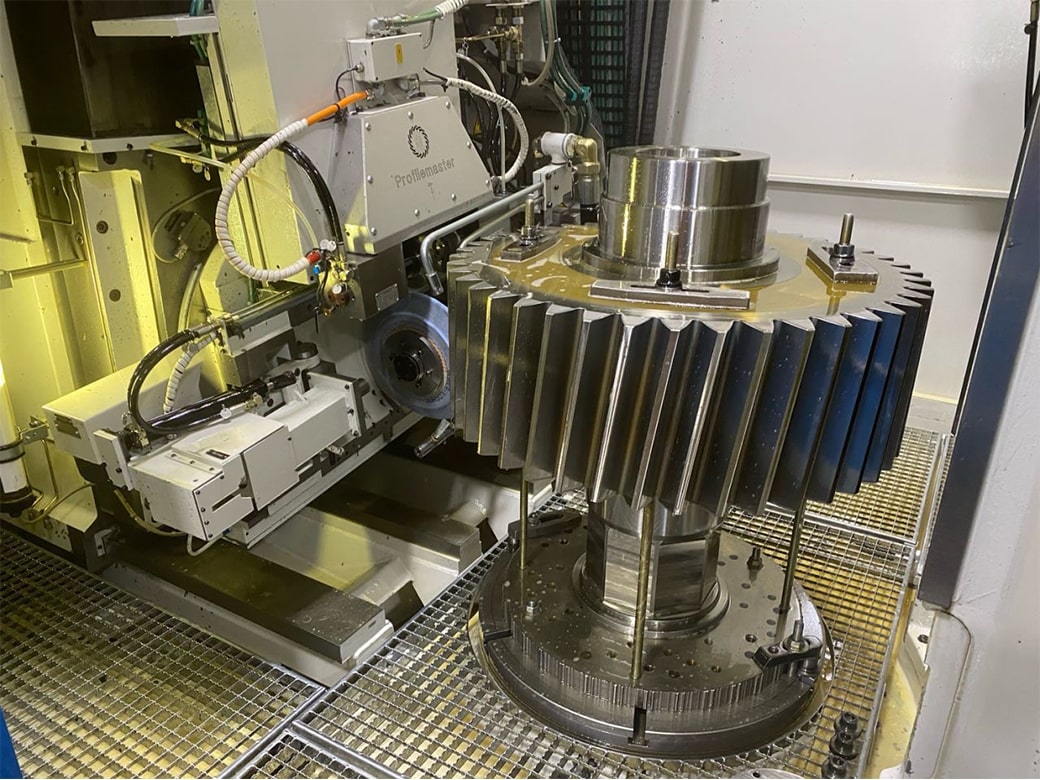

Preet Brothers Limited | Long Product Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects with annual capacity up to 1,000,000 Tons like: Rebar Rolling Mills, Wire Rod Rolling Mills, Bar Rolling Mills, Light Section Rolling Mills, Medium Section Rolling Mills, Heavy Section Rolling Mills. Besides complete plants Preet Brothers Limited | Long Product Hot Rolling Mill Division also under-take custom built design equipment’s based on the latest technology for various rolling mill equipment and systems like Rebar Rolling Mills | SBQ Rolling Mills | Wire Rod & Bar Rolling Mills | Small Section Rolling Mills | Medium Section Rolling Mills | Heavy Section Rolling Mills On Turnkey Bases (EPC & EP&S). Reheating Furnaces for Rolling Mills | Housingless stands for Hot Rolling Mills | Convertible Housingless Stands for Hot Rolling Mills | Universal Housingless Stands for Section Rolling Mills | Cantilever Stands for Hot Rolling Mills | Wirerod Mono-Block for Hot Rolling Mills | Sizing Mills for Hot Rolling Mills | Crank Shears for Hot Rolling Mills | Flying Shears for Hot Rolling Mills | Crop & Cobble Shears for Hot Rolling Mills | Crank cum Flying Dividing shears for Hot Rolling Mills | Thermo-processing units (TMT Plants) for Hot Rolling Mills | Harden Ground Gears & Gear boxes & Profile Ground Gears & Gear boxes | Entry and Exit Roller Guides Harden & Profile Ground Gears & Gear boxes | Slitting Guide boxes for 2 / 3 / 4 / 5 / 6 slitting Harden & Profile Ground Gears & Gear boxes | Sliding apron (Braking Slide) Rake type Cooling beds Harden & Profile Ground Gears & Gear boxes | Cold Shears of various sizes (150-1500Tons) | Dispatch & Bundling systems | Bar counters | Magnetic Stackers for Section handling | Single / Multi Groove Straighteners for on-line & off-line application in section rolling mill | Hot Saws & Cold Saws for Section Rolling Mill | Roll Changing Robots & Tilters for Rebar Rolling Mills | Preet Brothers Limited Roll-pass designs for slitting, angles, channels, I-beams & H-beams. Latest technology and high productivity of our plants: Guided by these concepts, we supply a complete scope of any green-field rolling mill for long products, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. Technical department @Preet Brothers Limited, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

PREET BROTHERS LIMITED | FLAT PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE:

Preet Brothers Limited | Flat Products Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects like: Narrow Strip Rolling Mills with annual capacity up to 1,400,000 Ton | Hot Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Hot Plate Rolling Mills with annual capacity up to 3,000,000 Ton | Continuous Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Wide Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Wide Plate Rolling Mills On Turnkey Bases (EPC). Latest technology and high productivity of our plants: guided by these concepts, we supply a complete scope of any green-field rolling mill for rolling hot flats products rolling mills, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. The Technical department, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

PREET BROTHERS LIMITED | FLAT PRODUCTS COLD ROLLING MILL & PROCESSING LINES DIVISION | A PREET ENTERPRISE:

Preet Brothers Limited has been serving steel industry for last four decades, Preet Brothers Limited is known for its versatile manufacturing capabilities mainly and has four verticals Hot Rolling Mill | Long Product Rolling Mills | Flat Products Rolling Mill Division. This makes Preet Brothers a front-runner company involved in manufacturing high performance and reliable Hot Rolling Mills for Long and Flat Products. We also offer Individual Rolling Mill equipment’s & Components for Hot Rolling Mill Plants. Preet Brothers Limited conducts technical feasibility studies for modernization of existing Hot Rolling Mill Plants as well as installation of individual components for Cold Rolling and Skin Pass Mill for Ferrous & Non- Ferrous | DCR Mills | Hot and cold rolled coil slitting Lines | Hot and cold rolled coil cut to length lines | Continues Galvanizing Lines wet flux / NON-OX | Continues Galvanizing Lines | Colour Coating Lines | Semi continues/ Push Pull Pickling Lines | High speed trimming-Cum-Rewinding Lines | Tension levelling lines | Annealing & Pickling lines for S.S. | Electrolytic Cleaning line | Terminal equipment’s for various lines as per customers design / drawings Furnace NON-OX | Cold Rolling Mills And Skin Pass Mill For Ferrous & Non-Ferrous | Galvanizing Lines |CGL) ( Furnace Type & Wet Flux Type) | Colour Coating Lines (CCL) | Electrolytic Cleaning Line | Tension Levelling Lines (TLL) | Bright Annealing (BA) Line For Stainless Steel | Annealing & Pickling Lines For S.S. | H & T Line | Hot Rolled Coils Slitting Lines | Cold Rolled Coil Slitting Lines | Cut To Length Hr, Cr And End Lap CTL | Semi Continuous Pickling Lines / Push Pull Pickling Lines | Corrugating Machines | High Speed Trimming-Cum-Rewinding Line | Oil Film Bearings | Service Solutions For Rolling Mills And Process Lines | Modernization Of Plate Rolling Mills | Flexible High-Performance Plants For Hot Strip Mills | Complete Solutions For Electrics And Automation (Level 1, Level 2, Level 3 With PREET-PTSW) | High-Performance Hot Strip Rolling Mills | Reversing Cold Mills | Compact Cold Mills | Multi roll Mill Stands For Stainless-Steel Strip | Skin-Pass Mills For A Perfect Finish | Hydraulic Systems | Continuous Casting Machines & Rolling Mill Equipment for Flat Products and Pipe Mill. Our products are entirely manufactured, assembled and tested in our top – class shop, and delivered worldwide. During planning, design, construction, assembly and putting into operation of our plants, our know-how guarantees high equipment availability and operating safety. Our product range includes: Casting Machines | Hot Strip Mill equipment | Plate and Steckel Mill equipment | Plate and Strip Levellers | Down coilers | Plate Shears (Rocking Type and Guillotine Type) | Rotary Crop Shears | Rotary Edge Trimming Shears | Skin-Pass Mill | 3Z High Mill.

PREET BROTHERS LIMITED | EPC DIVISION | A PREET ENTERPRISE:

PREET GROUP proudly introducing PREET-EPC for moving the Steel Industry to new heights by providing C to C Solution (Concept to Commissioning Solutions) for Iron Making, Steel Melting Shop, Power Plants, Rolling Mill Plants of Long & Flat products for Producing Bar Rolling Mills / Rebars Rolling Mills, Wire Rod Rolling Mills and Section Rolling Mills & Narrow Strips Rolling Mills. The company has earned the name and it’s recognized as leading EPC & EPCF solution provider our main Areas of Activity are as follows: Iron Making projects including DRI Plants, Sinter Plants, Blast Furnaces | Steel making up-to 2-million-ton capacity using Electric Arc Furnaces, Induction Furnaces, Ladle Furnaces, Vacuum Degassing Units, Continuous Casting Machines | Steel Rolling Mill Projects up-to 3,000,000 Tons / Year capacity both for Flat Products & Long Products including Narrow Strip Rolling Mills, Wide Plate Rolling Mills, Stickle Coil Rolling Mills, Re-Bar Rolling Mills, Wire Rod Rolling Mills, Light Section / Profile Rolling Mills, Medium Section / Profile Rolling Mills, Light Section / Profile Rolling Mills Cold Rolling Mills & Processing Lines. Cold Rolling Mills And Skin Pass Mill For Ferrous & Non-Ferrous | Galvanizing Lines (CGL) ( Furnace Type & Wet Flux Type) | Colour Coating Lines (CCL) | Electrolytic Cleaning Line | Tension Levelling Lines (TLL) | Bright Annealing (BA) Line For Stainless Steel | Annealing & Pickling Lines For S.S. | H & T Line | Hot Rolled Coils Slitting Lines | Cold Rolled Coil Slitting Lines | Cut To Length HR, CR And End Lap CTL | Semi Continuous Pickling Lines / Push Pull Pickling Lines | Corrugating Machines | High Speed Trimming-Cum-Rewinding Line | Oil Film Bearings | Service Solutions For Rolling Mills And Process Lines | Modernization Of Plate Rolling Mills | Flexible High-Performance Plants For Hot Strip Mills | Complete Solutions For Electrics And Automation (Level 1, Level 2 & Level 3) | High-Performance Hot Strip Rolling Mills | Reversing Cold Mills | Compact Cold Mills | Multi Roll Mill Stands For Stainless-Steel Strip | Skin-Pass Mills For A Perfect Finish | Hydraulic Systems

DKD IKJOT UNITED | CNC MACHINE BUILDING DIVISION | A PREET ENTERPRISE.

DKD Ikjot United | CNC Machine Building Division | A Preet Enterprise is the one of the largest PREET Enterprise with wide range of machine shop products like CNC Double column Vertical Machining Centres (VMC), CNC Roll Turning Lathes, CNC Roll Lathes, CNC Notching & Branding Machines, CNC VTL & CNC Special Purpose Machines (up to 20 axes). DKD Ikjot United CNC machine building is now placed among the most valuable CNC machine building brands Worldwide. These technology sectors demand a high degree of precision, efficiency and reliability – technical characteristics that are ensured by DKD IKJOT UNITED (IU) through an assembly that is defined down to the smallest detail, a high production depth and an unlimited desire to innovate. The machines are therefore energy-efficient and maintenance friendly and provide high quality – ideal conditions for the maximum use over many decades. Integrated into an owner-managed globally active group of companies with worldwide activities DKD Ikjot United ensures the flexibility which is necessary for customers in order to invest in production machines of this magnitude & which ensures a solid foundation for a long-term business partnership. Our responsible personnel contribute to this via our Worldwide sales and service network. They continuously develop individual solutions in close co-operation with the customer, and in this way ensure an endless market-oriented, development & expansion. DKD Ikjot United Lathes are the result of experience in the manufacturing of machine tools combined with outstanding reliability and the application of state-of-the-art technologies. DKD Ikjot United offers Heavy – Duty Turning Lathes with working ranges with workpiece diameters of 3,000 mm and weights of 200 tons. Turning large workpieces is a highly demanding application for a machine tool. Along with highly precise processing, the focus is on sturdy design, reliability and longevity of the machine. Producers of rotationally symmetrical workpieces, such as forges or roll manufacturers, achieve the highest efficiency with lathes by DKD Ikjot United The integration of milling heads, logo milling units or other optional equipment allows for the performance of very complex machining tasks in one single setup. With its NWD series, heavy-duty lathes with hydrostatic guidance systems, and the smaller lathes of the P series, DKD Ikjot United offers customized machines for the processing of, for example, Section Rolls, Forged Shafts or Rotors with a maximum of precision. DKD Ikjot United has also developed solutions for roll rings. The product range is complemented by the outstanding DKD Ikjot United service – comprehensive consulting from the earliest stages of a project, developing an application concept that is tailored to your needs and a broad range of after sales services. DKD Ikjot United Equipment’s sectors: Forges & Foundries | Long Product Rolling Mills | Paper Industries | Roll Manufacturing | Steel Industries | Service Industries | Oil & Gas Industries | General Industries | Plastic Industries | Automobile Industries.

SANJOG CRANES | CRANE DIVISION | A PREET ENTERPRISE.

SANJOG Cranes | Crane Division | A Preet Enterprise Has Successfully Designed, Built And Executed Small, Medium And Mega Size Hoists | Overhead Cranes | Components For Cranes | Gantry Cranes | Jib Cranes | Transfer Carts | Cantilever Cranes | Other Types Of Lifting Elements. The Bridge cranes (also referred to as Overhead cranes) are cranes with a lifting system like hoist or open winch. If you need an overhead crane that increases productivity, enhances safety and helps minimize your maintenance costs, look to SANJOG Cranes & Components, one of top crane manufacturer. We design and manufacture a full range of standardized and custom engineered overhead cranes and crane kits that are relied on by crane builders and end-users in multiple industries, in multiple applications and in more than 70 countries on five continents. Overhead cranes from SANJOG Cranes & Components come in two styles, box girder and standard profile, and feature an integrated lifting mechanism, typically a hoist or open winch. Our optimized combination of crane structure and lifting mechanism (whether for lifting, cross travel or long travel) reduces hook approaches and maximizes the useful area of your facility. Hoists come in under running, top running, foot mount and built-up designs. End Trucks are available in top running, top running bogey and underhung types. Overhead Cranes from 500 kg to 400 ton Standardized Construction Versatile modular design Adaptable to multiple applications Highly reliable components Robot Welded Maximum strength Highest quality Uniform welds Better use of space with our bridge cranes. The optimized combination of structures and mechanisms (lifting, cross travel and long travel) on these cranes reduce hook approaches and that maximize the useful areas. Construction of structural welded elements, done with automated and robotic systems, which guarantee the repeatability of welding processes and high product quality. Steel making is a continuous process. The melt shop is a hazardous environment of extreme heat, choking dust, hot metal and naked flame. Melt shop cranes must be able to lift and carry buckets of liquid metal safely. Making molten steel The ingredients for steel come from two main sources: raw materials and scrap. Because they are different substances, they are treated separately. Iron ore and coking coal are combined in a direct reduction process to produce solid metallic iron. A ladle crane lifts the melted iron for mixing with scrap to create molten steel. The scrap coming from the scrapyard is loaded in the furnace with an overhead charging crane. The main hoisting machinery lifts the bucket to the furnace for melting. An auxiliary hoist on the crane opens and closes the bucket during loading. Depending on the facilities, a basic oxygen furnace or an electric arc furnace could be used. In a full-size mill, the scrap is added to iron, but in a Preet mini mills, the scrap might be the only raw source of liquid metal. Casting into shape From the initial furnace blast in the steel creation process, a teeming crane helps to mix the molten metal in the right proportions. Once the mix is right, liquid steel is then cast into shape. Tundish cranes are typically utilized in tundish maintenance and handling. Multi-function cranes The charging crane, ladle crane, teeming crane, and tundish crane are all quite similar and can be defined by their location and function in the plant. They are usually overhead traveling cranes that are fitted with special attachments to lift the giant ladles that contain liquid metal. They often perform more than one function and are used as backup for each other. Auxiliary hoists can be attached for scrap charging and maintenance functions, such as cleaning the empty ladles or lifting the furnace shell. Up for the challenge Every SANJOG Cranes hot metal crane is designed specifically for the unique challenges of this environment. Increased working coefficients, a differential gear reducer, redundancy in all critical systems, a backup brake on the rope drum, and motion limiters are just some of the technologies we employ. Automation of repetitive movements and an air-conditioned, ergonomic cabin keep the driver comfortable and able to concentrate on the task at hand. Keep your crane healthy To help the cranes last, exposed areas are protected against heat and dust. Our cranes can be fitted with remote monitoring so you can follow the operating statistics of the crane throughout its lifecycle. Routine maintenance helps to prevent unexpected faults, minimize downtime and maximize the productivity of the crane.

SANJOG PEB | PE BUILDING DIVISION | A PREET ENTERPRISE.

SANJOG PEB | PE Building Division | A Preet Enterprise Building Systems is one of the largest pre-engineered steel building (PEB) companies in the world and is a 100% subsidiary of Preet and multi-billion dollar business conglomerate Industries, one of the largest privately-owned companies in India. Its product list consists of pre-engineered steel buildings (PEB) applicable for factories, warehouses, metro rails, supermarkets, aircraft hangars, sports stadiums, auditoriums, etc. Other products include structural steel, sandwich panels, storage solutions, Sanjog Roof (SR), Sanjog Wall (SW), Sanjog Deep Decking Panel and Sanjog Standing Seam Panel (SSS-600). Sanjog offers one of the most comprehensive Pre-engineered steel buildings-PEB product portfolios globally, with applications in major market segments including heavy industry, infrastructure, high-rise buildings, warehouses, factories, oil and gas and leisure structures. The company maintains a strong reputation for delivering customer- designed and cost- effective solutions for steel buildings that are manufactured to the highest quality standards, and a commitment to providing top class service to its customers. Our commitment to excellence provides unmatched product quality, coupled with speed, safety and superior sales services. We at SANJOG PEB | PE Building Division | A Preet Enterprise offer a worry-free solution to our clients. We go that extra-mile through our systems, process and our internal orientation to ensure that commissioning a Sanjog project is a seamless and effortless experience for our clients. Pre-engineered steel buildings (PEB) are a steel structures built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascia’s, canopies, crane systems, insulation etc., based on the customer’s requirements. All the steel buildings are custom designed to be lighter in weight and high in strength. Thus steel building designs have become more flexible, durable and adaptable over the last four decades which has made steel one of the preferred materials for building construction. PEB’s are ideal for non-residential and wide-span low-rise buildings. Some of the key advantages of PEB include economical in cost, factory controlled quality, durability, longevity, flexibility in expansion, environmentally friendly, faster installation, etc. Pre-engineered steel buildings are used for diverse applications such as factories, warehouses, showrooms, supermarkets, aircraft hangars, metro stations, offices, shopping malls, schools, hospitals, community buildings and many more. As a leading PEB manufacturer, SANJOG PEB provides the complete service of engineering, fabrication and erection thus ensuring better quality control at every stage of the process. Pre-engineered steel buildings consists of following components: Primary Members / Main Frames | Secondary Members / Cold Formed Members | Roof & Wall Panels | Accessories, Buyouts, Crane System, Mezzanine System, Insulation, etc. | Sandwich Panels.

Bevel Gears and Gear Boxes

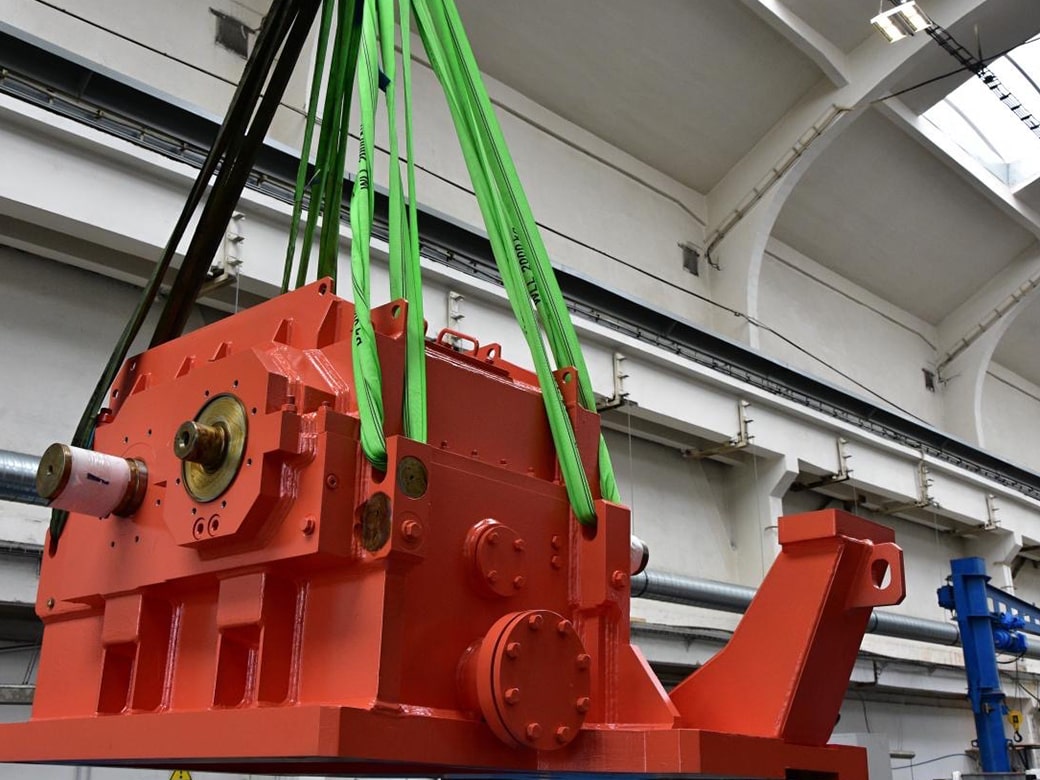

Custom Built Heavy Duty Gear Boxes for Rolling Mills

Gear Box Assembly Shop at PREET

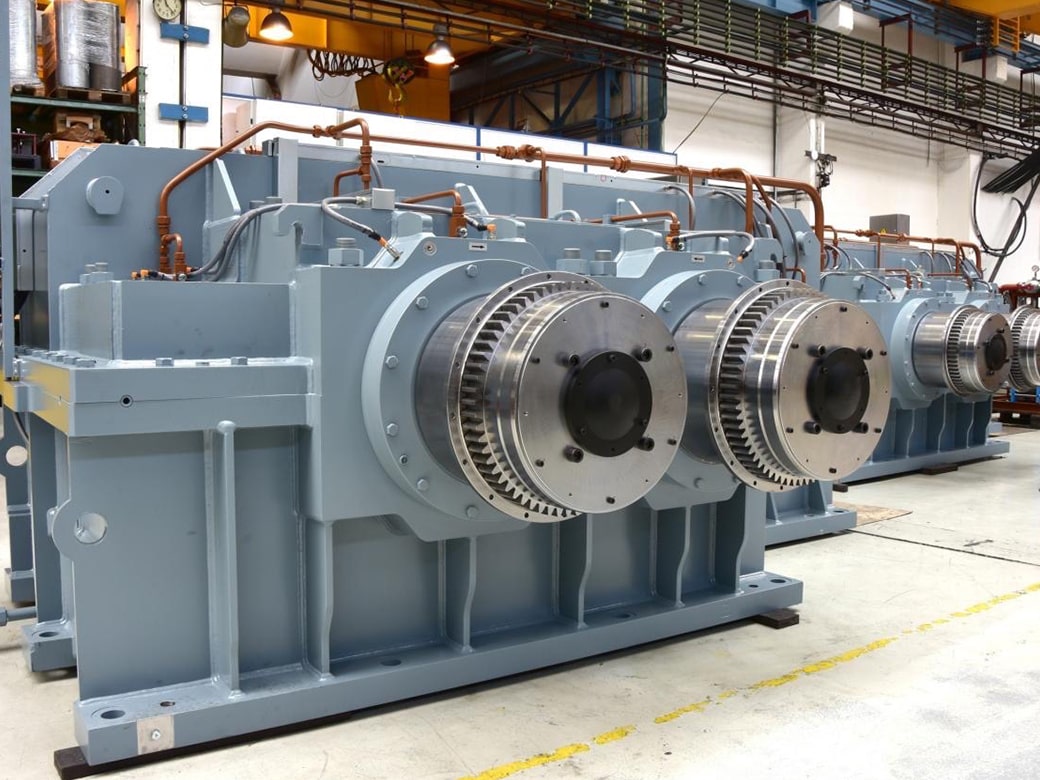

Gear Boxes for Hot Rollings Mills

Hardend and Profile Ground Gear Boxes for Rebar Rolling Mills

Heavy Duty Cardan Shafts for Hot Strip Mills

Heavy Duty Double Column Machining Centre

Heavy Duty Hardened And Ground Gear Boxes at PREET

Profile Ground Gear Boxes for Steel Industry