Preet Brothers Limited | Long Products Rolling Mill Stands | A Preet Enterprises

Designing & Developing All Types Of Hot Rolling Mill Stands Like Cantilever Stands Horizontal & Vertical Housing Less Rolling Mill Stands & Universal Housing Less Rolling Stands. The Housing Less design, in short HLS, are the backbone of modern rolling mills. The HLS design allows the use of the HLS stand cartridges in all the possible configurations like horizontal, vertical, convertible and universal. Housing Less concept is suitable for roughing mills, intermediate mils and finishing mills for Rebar rolling mills, Bar rolling mills, Wire rod rolling mills, Section rolling mills. Mill stand sizes are varied in accordance with the required dimensions of rolls and necks, the size & shape of rolling pass, the groove design as well as the transmission and drive characteristics. Preet design department models all load data to determine all the process variables and select the correct stand size. The Housing Less stands operate in Bar mills, Wire rod mills, Section mills and Combined plants. The main features of the Housing Less design is Conservative component sizing criteria and general philosophy in order to achieve rigidity and compactness of each unit, Low roll deflection modulus, Long life multi-roller bearings with chocks self-alignment under load, Balancing of backlash between chocks, Rest bars designed to allow easy and fine adjustment of guide boxes. These are the major benefits during operation of Finished product matching required tolerance on geometry and size, stricter weight control, Time saving during stand changing with off-line roll changing, Flexibility of operation, same stand unit used in horizontal, vertical, convertible and universal configurations, minimization of spare parts inventory, Highly reduced maintenance time and costs, due to a reduced number of components and easy access, Automated gap adjustment, Integration in fully automatic control for Rebar rolling mills, Bar rolling mills, Wire rod rolling mills, Section rolling mills. The Stand Quick Roll Changing Robots System for Rebar rolling mills, Bar rolling mills, Wire rod rolling mills, Section rolling mills. In order to reduce changing times, the intermediate and finishing stands are usually equipped with

a quick roll change transfer table. Stands for the next rolling cycle are positioned via the plant crane on a transfer table. Stands to be sent to maintenance are pushed off-line by hydraulic cylinders on the table alongside the new stands. A single shift of the transfer table positions the new stands in front of the mill before they are pulled in-line hydraulically. Customers feedback is changing times of approx. 20 minutes using this system for rebar rolling mills, bar rolling mills, wire rod rolling mills, section rolling mills. The Universal Housing Less Stand for Section rolling mills. The key benefit of rolling sections in universal stands is that the entire section is simultaneously and harmoniously shaped. The symmetrical arrangement and the separate adjustment of horizontal and vertical rolls allows stresses in the section to be reduced and improved tolerances to be achieved. The design of the stand is based on the proven Housing Less series with a sturdy vertical roll being added for universal operation. The configuration ensures quick program changes. This solution allows high rigidity combined with extreme flexibility, as the modular design allows the stands to be prepared either in a 2-high configuration or in a universal configuration.

PREET BROTHERS LIMITED | LONG PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE

Preet Brothers Limited | Long Product Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects with annual capacity up to 1,000,000 Tons like: Rebar Rolling Mills, Wire Rod Rolling Mills, Bar Rolling Mills, Light Section Rolling Mills, Medium Section Rolling Mills, Heavy Section Rolling Mills. Besides complete plants Preet Brothers Limited | Long Product Hot Rolling Mill Division also under-take custom built design equipment’s based on the latest technology for various rolling mill equipment and systems like Rebar Rolling Mills | SBQ Rolling Mills | Wire Rod & Bar Rolling Mills | Small Section Rolling Mills | Medium Section Rolling Mills | Heavy Section Rolling Mills On Turnkey Bases (EPC & EP&S). Reheating Furnaces for Rolling Mills | Housingless stands for Hot Rolling Mills | Convertible Housingless Stands for Hot Rolling Mills | Universal Housingless Stands for Section Rolling Mills | Cantilever Stands for Hot Rolling Mills | Wirerod Mono-Block for Hot Rolling Mills | Sizing Mills for Hot Rolling Mills | Crank Shears for Hot Rolling Mills | Flying Shears for Hot Rolling Mills | Crop & Cobble Shears for Hot Rolling Mills | Crank cum Flying Dividing shears for Hot Rolling Mills | Thermo-processing units (TMT Plants) for Hot Rolling Mills | Harden Ground Gears & Gear boxes & Profile Ground Gears & Gear boxes | Entry and Exit Roller Guides Harden & Profile Ground Gears & Gear boxes | Slitting Guide boxes for 2 / 3 / 4 / 5 / 6 slitting Harden & Profile Ground Gears & Gear boxes | Sliding apron (Braking Slide) Rake type Cooling beds Harden & Profile Ground Gears & Gear boxes | Cold Shears of various sizes (150-1500Tons) | Dispatch & Bundling systems | Bar counters | Magnetic Stackers for Section handling | Single / Multi Groove Straighteners for on-line & off-line application in section rolling mill | Hot Saws & Cold Saws for Section Rolling Mill | Roll Changing Robots & Tilters for Rebar Rolling Mills | Preet Brothers Limited Roll-pass designs for slitting, angles, channels, I-beams & H-beams. Latest technology and high productivity of our plants: Guided by these concepts, we supply a complete scope of any green-field rolling mill for long products, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. Technical department @Preet Brothers Limited, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

Cantilever Stand for Rebar Rolling Mill

Cantilever stand for Wire Rod Rolling Mill

Cantilever Stands for Wire Rod Rolling Mills

Hot Strip Rolling Mill Stands

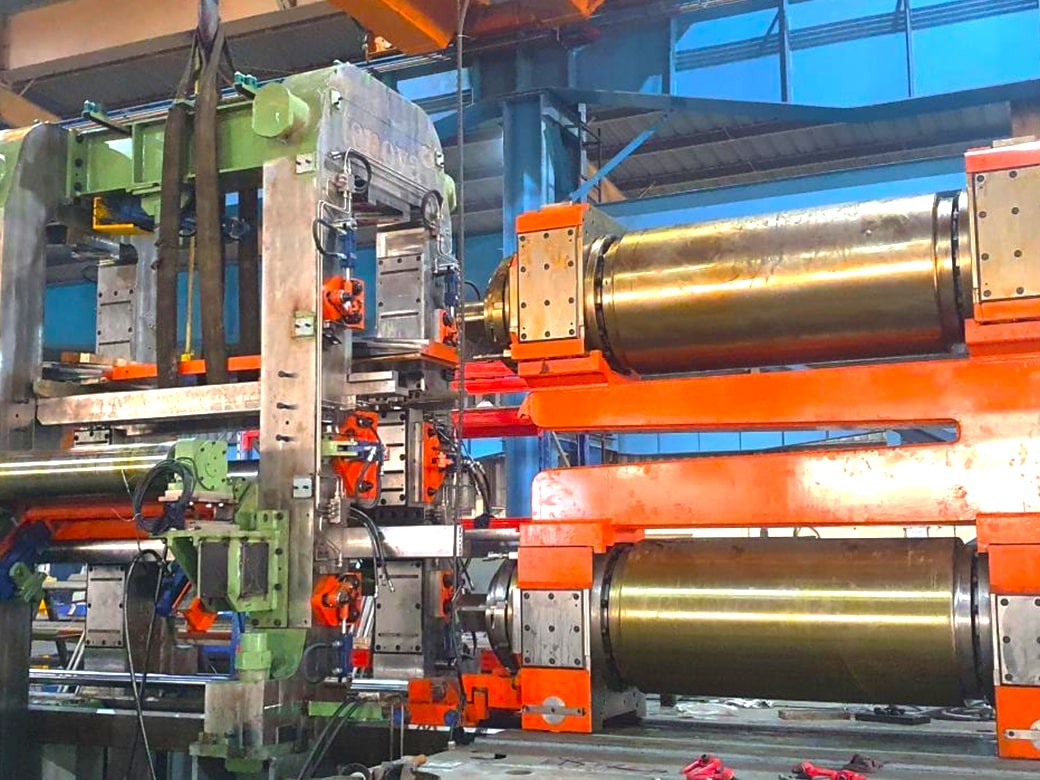

Housingless Section Rolling Mill Stand

Housingless Rebar Rolling Mill Stands

Housingless Stands for Rebar Rolling Mill

Housingless Stands for Wire Rod Rolling MIlls

Hot Strip Rolling Mill Stands

Prestressed Rebar Rolling Mill Stands

Roll Changing Robot for Housingless Rebar Rolling Mill Stands

Stands for Narrow Strip Rolling Mills

Hot Strip Rolling Mill Stands