Preet Brothers Limited | Flat Product Division | Hot Strip Rolling Mills

PREET BROTHERSLIMITED | FLAT PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE

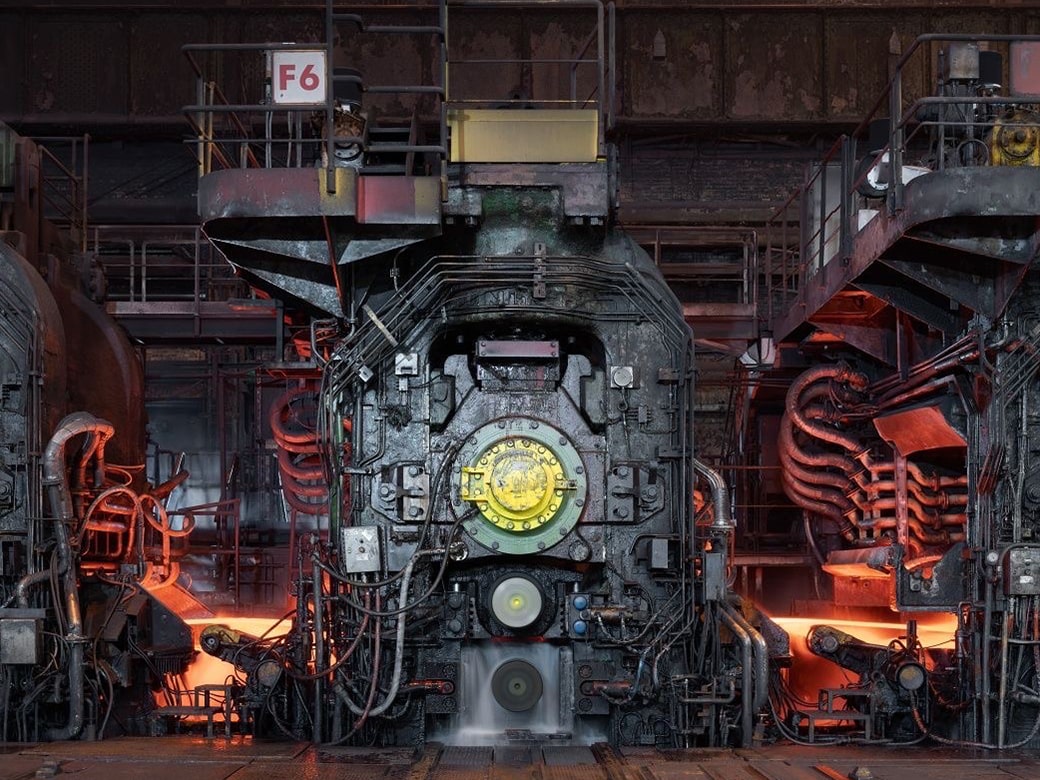

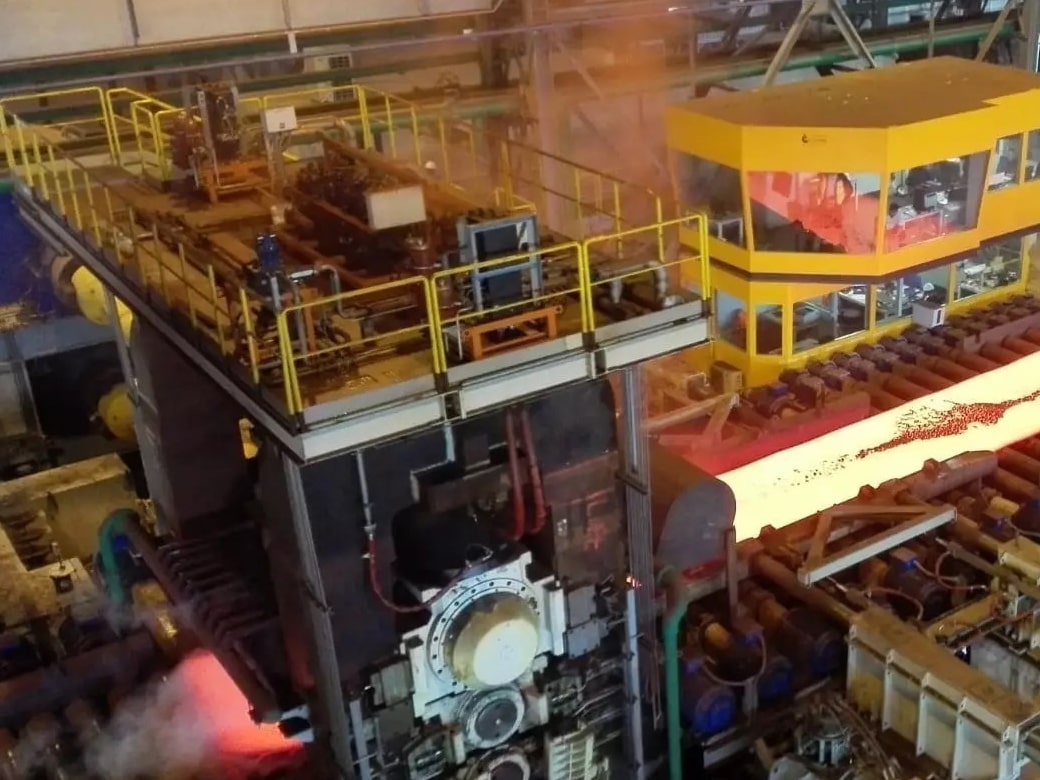

Preet Brothers Limited | Flat Products Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects like: Narrow Strip Rolling Mills Capacity: 300,000 – 1,400,000 T / Year | Hot Strip Rolling Mills Capacity: 500,000 – 3,000,000 T | Plate Rolling Mills Capacity: 500,000 – 3,000,000 T | Continuous Strip Rolling Mills Capacity: 500,000 – 3,000,000 T | Wide Strip Rolling Mills Capacity: 500,000 – 3,000,000 T | Wide Plate Rolling Mills On Turnkey Bases (EPC). Latest technology and high productivity of our plants: guided by these concepts, we supply a complete scope of any green-field rolling mill for rolling hot flats products, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. The Technical department, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer. Preet BrothersLimited | Flat Product Division | Hot Strip Rolling Mills. Our experienced team of engineers and design has offered modern solutions that perfectly match the demands of the market. Plant layout, design, and manufacture go hand-in-hand. Our success factors is the close intermeshing of development, design, and manufacture. All departments are under a single roof at the Preet Growth Shop site, so that continuous exchange is a matter of course. This kind of cooperation using the shortest possible routes guarantees the continuous holistic improvement of our products. What also counts is close contact with customers throughout the entire life cycle of their plant. All plants and components are designed individually by Preet BrothersLimited | Flat Product Division | Hot Strip Rolling Mills to meet the specific operational needs. To determine the process requirements, we apply methods, analyses or dynamic simulations such as those for deformation behaviour. Moreover, for design work, we use state-of-the-art 3D CAD systems. The core components of our hot strip mills, such as bending and shifting systems, hydraulic roll-gap adjustment systems, coiler mandrel valve stands or drive engineering, are manufactured by us in our 310,000 m2 workshop in Preet Growth Shop equipped with the most up-to-date machines. The range of manufacturing in our workshop extends from the production of high-quality welded structures, to machining operations with a powerful machine tools for innovative production processes, to the assembly and installation of heavy machinery. We install all mill stands, coilers and pipework to the customer’s requirements and carry out function tests and trial runs on special test facilities. This is how we achieve a high degree of efficiency and a long service life for these components – which are crucial to the product quality and the profitability of the plants. Preet BrothersLimited | Flat Product Division | Hot Strip Rolling Mills Design & offers Main components Like: Walking beam furnaces | High-pressure water descaler | Edger with 4-high reversing roughing stand | Heat retention hoods between R1 and finishing mill | Coil box | Drum Type Shear | Crank-type crop shear | High-pressure water descaler | Roller Tables with side guides Run out roller table | laminar cooling | Universal down coilers. Preet BrothersLimited | Flat Product Division | Hot Strip Rolling Mills design all the greenfield projects for Better process stability and higher yield. Our roughing mill stands are designed to produce straight and camber free transfer bars. That reduces rolling difficulties and cobble risks during finish rolling. Close geometrical strip tolerances, Our finishing mill stands are equipped for strip profile, contour, and flatness control.

PREET BROTHERS LIMITED | FLAT PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE

Preet Brothers Limited | Flat Products Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects like: Narrow Strip Rolling Mills with annual capacity up to 1,400,000 Ton | Hot Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Hot Plate Rolling Mills with annual capacity up to 3,000,000 Ton | Continuous Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Wide Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Wide Plate Rolling Mills On Turnkey Bases (EPC). Latest technology and high productivity of our plants: guided by these concepts, we supply a complete scope of any green-field rolling mill for rolling hot flats products rolling mills, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. The Technical department, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

PREET BROTHERS LIMITED | FLAT PRODUCTS COLD ROLLING MILL & PROCESSING LINES DIVISION | A PREET ENTERPRISE

Preet Brothers Limited has been serving steel industry for last four decades, Preet Brothers Limited is known for its versatile manufacturing capabilities mainly and has four verticals Hot Rolling Mill | Long Product Rolling Mills | Flat Products Rolling Mill Division. This makes Preet Brothers a front-runner company involved in manufacturing high performance and reliable Hot Rolling Mills for Long and Flat Products. We also offer Individual Rolling Mill equipment’s & Components for Hot Rolling Mill Plants. Preet Brothers Limited conducts technical feasibility studies for modernization of existing Hot Rolling Mill Plants as well as installation of individual components for Cold Rolling and Skin Pass Mill for Ferrous & Non- Ferrous | DCR Mills | Hot and cold rolled coil slitting Lines | Hot and cold rolled coil cut to length lines | Continues Galvanizing Lines wet flux / NON-OX | Continues Galvanizing Lines | Colour Coating Lines | Semi continues/ Push Pull Pickling Lines | High speed trimming-Cum-Rewinding Lines | Tension levelling lines | Annealing & Pickling lines for S.S. | Electrolytic Cleaning line | Terminal equipment’s for various lines as per customers design / drawings Furnace NON-OX | Cold Rolling Mills And Skin Pass Mill For Ferrous & Non-Ferrous | Galvanizing Lines |CGL) ( Furnace Type & Wet Flux Type) | Colour Coating Lines (CCL) | Electrolytic Cleaning Line | Tension Levelling Lines (TLL) | Bright Annealing (BA) Line For Stainless Steel | Annealing & Pickling Lines For S.S. | H & T Line | Hot Rolled Coils Slitting Lines | Cold Rolled Coil Slitting Lines | Cut To Length Hr, Cr And End Lap CTL | Semi Continuous Pickling Lines / Push Pull Pickling Lines | Corrugating Machines | High Speed Trimming-Cum-Rewinding Line | Oil Film Bearings | Service Solutions For Rolling Mills And Process Lines | Modernization Of Plate Rolling Mills | Flexible High-Performance Plants For Hot Strip Mills | Complete Solutions For Electrics And Automation (Level 1, Level 2, Level 3 With PREET-PTSW) | High-Performance Hot Strip Rolling Mills | Reversing Cold Mills | Compact Cold Mills | Multi roll Mill Stands For Stainless-Steel Strip | Skin-Pass Mills For A Perfect Finish | Hydraulic Systems | Continuous Casting Machines & Rolling Mill Equipment for Flat Products and Pipe Mill. Our products are entirely manufactured, assembled and tested in our top – class shop, and delivered worldwide. During planning, design, construction, assembly and putting into operation of our plants, our know-how guarantees high equipment availability and operating safety. Our product range includes: Casting Machines | Hot Strip Mill equipment | Plate and Steckel Mill equipment | Plate and Strip Levellers | Down coilers | Plate Shears (Rocking Type and Guillotine Type) | Rotary Crop Shears | Rotary Edge Trimming Shears | Skin-Pass Mill | 3Z High Mill.

PREET BROTHERS LIMITED | EPC DIVISION | A PREET ENTERPRISE

PREET GROUP proudly introducing PREET-EPC for moving the Steel Industry to new heights by providing C to C Solution (Concept to Commissioning Solutions) for Iron Making, Steel Melting Shop, Power Plants, Rolling Mill Plants of Long & Flat products for Producing Bar Rolling Mills / Rebars Rolling Mills, Wire Rod Rolling Mills and Section Rolling Mills & Narrow Strips Rolling Mills. The company has earned the name and it’s recognized as leading EPC & EPCF solution provider our main Areas of Activity are as follows: Iron Making projects including DRI Plants, Sinter Plants, Blast Furnaces | Steel making up-to 2-million-ton capacity using Electric Arc Furnaces, Induction Furnaces, Ladle Furnaces, Vacuum Degassing Units, Continuous Casting Machines | Steel Rolling Mill Projects up-to 3,000,000 Tons / Year capacity both for Flat Products & Long Products including Narrow Strip Rolling Mills, Wide Plate Rolling Mills, Stickle Coil Rolling Mills, Re-Bar Rolling Mills, Wire Rod Rolling Mills, Light Section / Profile Rolling Mills, Medium Section / Profile Rolling Mills, Light Section / Profile Rolling Mills Cold Rolling Mills & Processing Lines. Cold Rolling Mills And Skin Pass Mill For Ferrous & Non-Ferrous | Galvanizing Lines (CGL) ( Furnace Type & Wet Flux Type) | Colour Coating Lines (CCL) | Electrolytic Cleaning Line | Tension Levelling Lines (TLL) | Bright Annealing (BA) Line For Stainless Steel | Annealing & Pickling Lines For S.S. | H & T Line | Hot Rolled Coils Slitting Lines | Cold Rolled Coil Slitting Lines | Cut To Length HR, CR And End Lap CTL | Semi Continuous Pickling Lines / Push Pull Pickling Lines | Corrugating Machines | High Speed Trimming-Cum-Rewinding Line | Oil Film Bearings | Service Solutions For Rolling Mills And Process Lines | Modernization Of Plate Rolling Mills | Flexible High-Performance Plants For Hot Strip Mills | Complete Solutions For Electrics And Automation (Level 1, Level 2 & Level 3) | High-Performance Hot Strip Rolling Mills | Reversing Cold Mills | Compact Cold Mills | Multi Roll Mill Stands For Stainless-Steel Strip | Skin-Pass Mills For A Perfect Finish | Hydraulic Systems

Backup Rolls for Hot Strip Rolling Mills

Cardan Shafts for Hot Strip Rolling Mills

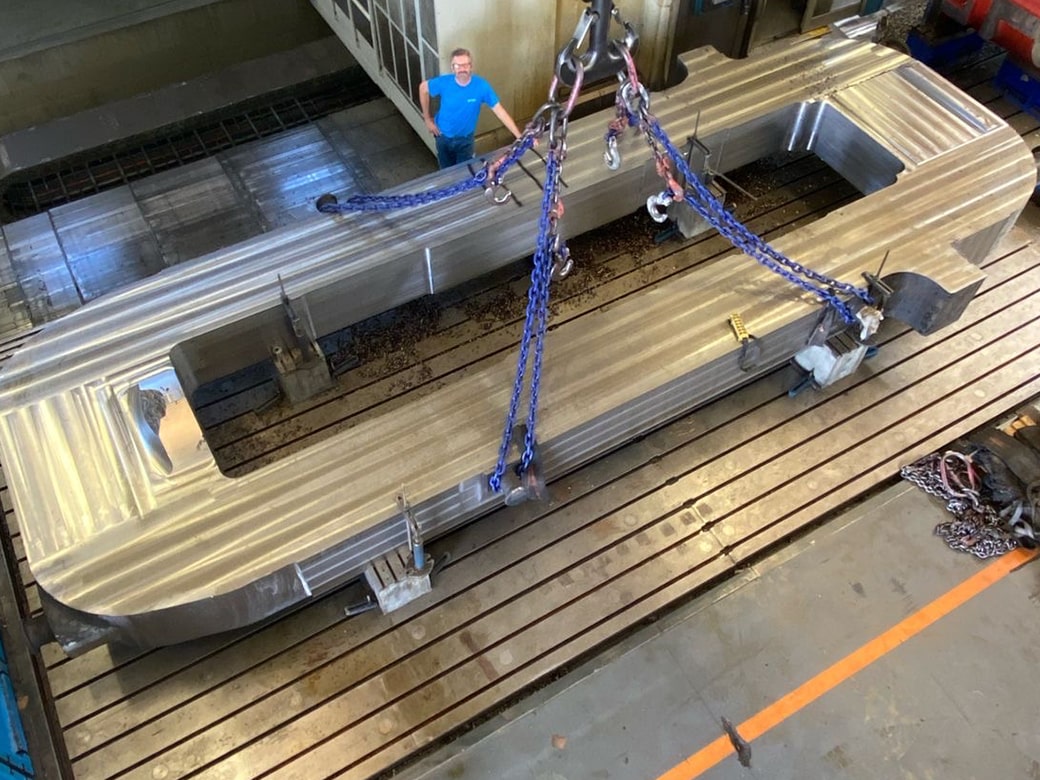

Chocks for Hot Strip Rolling Mills

Hardered and Ground Gear Box for Hot Strip Rolling Mills

Hot Rolled Coils

Hot Strip Rolling Mills

Hot Strip Rolling Mills

Hot Strip Roughing Rolling Mill

Housing Machining for Hot Strip Rolling Mill

Housing Under Machining for Hot Strip Rolling Mills

Housing, Casting for Hot Strip Rolling Mills

Laminar Cooling for Hot Strip Rolling Mills

Roughing Mills for Hot Strip Rolling Mills

Slabs for Hot Strip Rolling Mills