Preet Brothers Limited | Flat Product Division | Narrow Hot Strip Rolling Mills

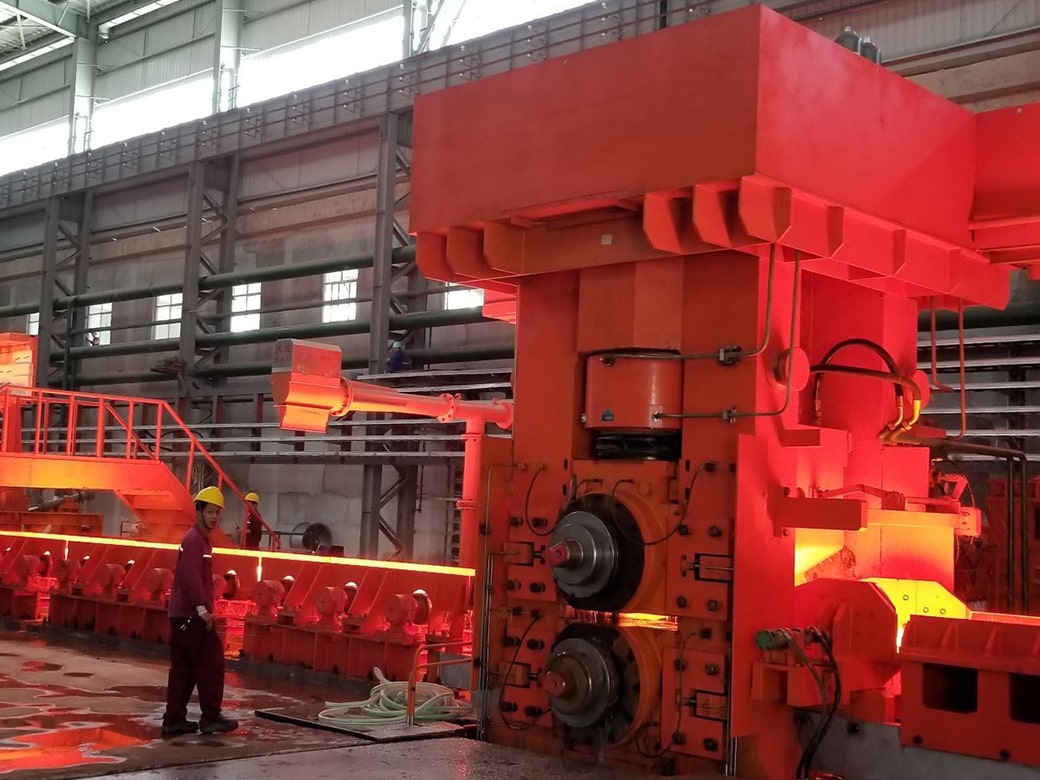

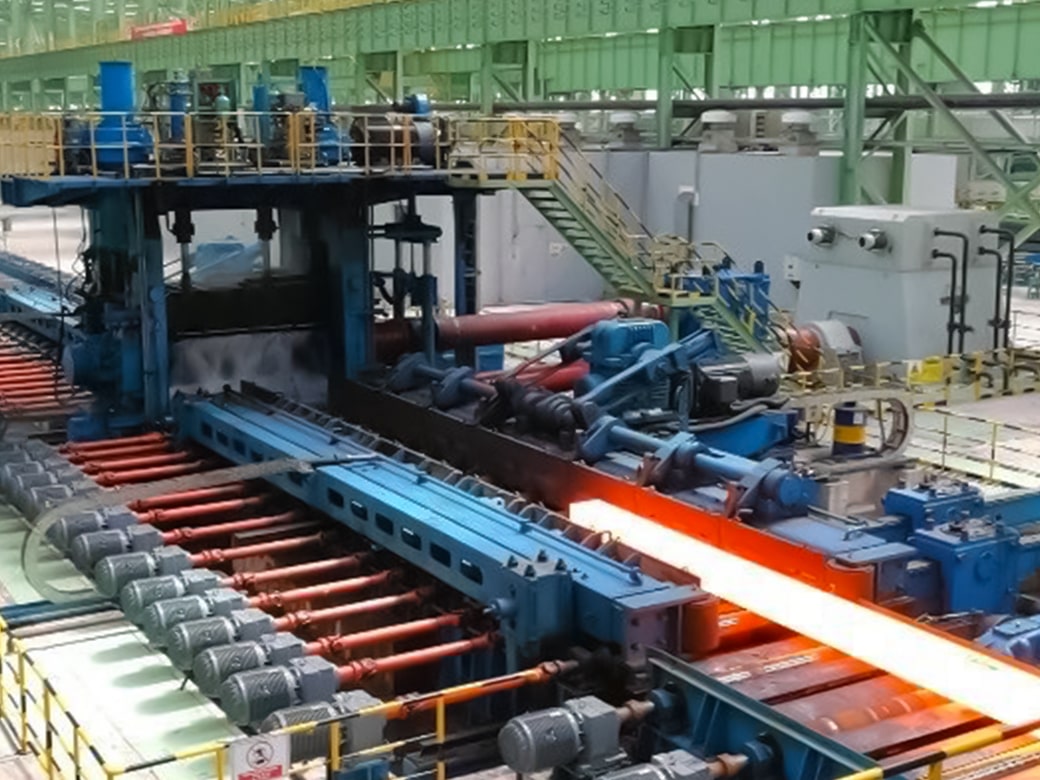

Preet Brothers Limited | Flat Product Division | Narrow Hot Strip Rolling Mills has designed, manufactured and successfully delivered Semi Continuous narrow Hot Strip Mill. Semi Continuous Hot Strip Mill which incorporates the latest proven technology and know-how available in the steel industry. Our experienced team of engineers and design has offered modern solutions that perfectly match the demands of the market. The specifications are mainly based on the capacity requirement. However, careful analysis of the production strategies as well current technology innovations and future trends in the steel industry are also equally considered. Additionally, local factors and constraints also played important role in the design of the plant and selection of the equipment. The design of the plant is flexible and has been studied to ensure: Easy handling | High productivity | High quality of final products | Low specific consumption | Simple maintenance. On the basis of this and with a low initial investment joint to reduce transformation cost, it’s possible to have a short time lag between investment and payback. Preet can also support with the following Optional Services on a special request of the buyer, commercial offer of these services can be submitted after freezing the scope: Master Layout Engineering Services. Civil Engineering Services. Structural and Building Engineering Services. Utility Engineering Services. Site Erection Supervision/ Implementation Services. Plant Commissioning Supervision/ Implementation Services. The demand for hot rolled strip is growing in multiple ways. To remain competitive, new and existing mills must meet this challenge in the best possible way. The production of hot strip is a key element of steel production. Since close to half of all steel produced is hot-rolled to strip, mills require maximum throughput and availability combined with geometrical precision and the ability to create optimum material properties. High-performance hot strip mills are designed for an annual capacity of up to 1,500,000 tons. They are usually equipped with two reversing roughing stands, seven finishing stands and two coilers Main Highlight of the project: Descaler for surface quality | Slab sizing press for flexible adjustment of slab width | Compact layout of the hot strip mill | Crop shear with cut optimization for low cropping losses Finishing stands in compact and maintenance- friendly design | Work roll quick-change system | Oil bearings for mounting the backup rolls | Gear unit with case-hardened bull gears and pinions | spindles for safe transmission of extremely high torques | Roll gap lubrication for reduction of roll force and roll torque | Looper technology for safe strip tracking behaviour Strip cooling with cooling concepts structured one above the other to achieve economic production of all steel grades Preet supplies the mills as integrated units with coordinated systems comprising mechanical equipment, electrical & automation systems, and process knowhow. The integrated solutions are based on the extensive knowledge of our engineers in relation to the options of plant engineering, detailed process engineering knowhow and our expertise in the design and manufacture of core components in our own workshops in India. All of our customers have major benefits from our plants, robust engineering with a secure future for manufacturing modern steel grades in top-class product quality within extremely close geometrical and metallurgical tolerances plus high yield and availability. High profitability thanks to Eco-plants components fitted out to reduce energy use and ensure high process stability.

PREET BROTHERS LIMITED | FLAT PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE

Preet Brothers Limited | Flat Products Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects like: Narrow Strip Rolling Mills with annual capacity up to 1,400,000 Ton | Hot Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Hot Plate Rolling Mills with annual capacity up to 3,000,000 Ton | Continuous Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Wide Strip Rolling Mills with annual capacity up to 3,000,000 Ton | Wide Plate Rolling Mills On Turnkey Bases (EPC). Latest technology and high productivity of our plants: guided by these concepts, we supply a complete scope of any green-field rolling mill for rolling hot flats products rolling mills, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. The Technical department, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

PREET BROTHERS LIMITED | FLAT PRODUCTS COLD ROLLING MILL & PROCESSING LINES DIVISION | A PREET ENTERPRISE

Preet Brothers Limited has been serving steel industry for last four decades, Preet Brothers Limited is known for its versatile manufacturing capabilities mainly and has four verticals Hot Rolling Mill | Long Product Rolling Mills | Flat Products Rolling Mill Division. This makes Preet Brothers a front-runner company involved in manufacturing high performance and reliable Hot Rolling Mills for Long and Flat Products. We also offer Individual Rolling Mill equipment’s & Components for Hot Rolling Mill Plants. Preet Brothers Limited conducts technical feasibility studies for modernization of existing Hot Rolling Mill Plants as well as installation of individual components for Cold Rolling and Skin Pass Mill for Ferrous & Non- Ferrous | DCR Mills | Hot and cold rolled coil slitting Lines | Hot and cold rolled coil cut to length lines | Continues Galvanizing Lines wet flux / NON-OX | Continues Galvanizing Lines | Colour Coating Lines | Semi continues/ Push Pull Pickling Lines | High speed trimming-Cum-Rewinding Lines | Tension levelling lines | Annealing & Pickling lines for S.S. | Electrolytic Cleaning line | Terminal equipment’s for various lines as per customers design / drawings Furnace NON-OX | Cold Rolling Mills And Skin Pass Mill For Ferrous & Non-Ferrous | Galvanizing Lines |CGL) ( Furnace Type & Wet Flux Type) | Colour Coating Lines (CCL) | Electrolytic Cleaning Line | Tension Levelling Lines (TLL) | Bright Annealing (BA) Line For Stainless Steel | Annealing & Pickling Lines For S.S. | H & T Line | Hot Rolled Coils Slitting Lines | Cold Rolled Coil Slitting Lines | Cut To Length Hr, Cr And End Lap CTL | Semi Continuous Pickling Lines / Push Pull Pickling Lines | Corrugating Machines | High Speed Trimming-Cum-Rewinding Line | Oil Film Bearings | Service Solutions For Rolling Mills And Process Lines | Modernization Of Plate Rolling Mills | Flexible High-Performance Plants For Hot Strip Mills | Complete Solutions For Electrics And Automation (Level 1, Level 2, Level 3 With PREET-PTSW) | High-Performance Hot Strip Rolling Mills | Reversing Cold Mills | Compact Cold Mills | Multi roll Mill Stands For Stainless-Steel Strip | Skin-Pass Mills For A Perfect Finish | Hydraulic Systems | Continuous Casting Machines & Rolling Mill Equipment for Flat Products and Pipe Mill. Our products are entirely manufactured, assembled and tested in our top – class shop, and delivered worldwide. During planning, design, construction, assembly and putting into operation of our plants, our know-how guarantees high equipment availability and operating safety. Our product range includes: Casting Machines | Hot Strip Mill equipment | Plate and Steckel Mill equipment | Plate and Strip Levellers | Down coilers | Plate Shears (Rocking Type and Guillotine Type) | Rotary Crop Shears | Rotary Edge Trimming Shears | Skin-Pass Mill | 3Z High Mill.

PREET BROTHERS LIMITED | EPC DIVISION | A PREET ENTERPRISE

PREET GROUP proudly introducing PREET-EPC for moving the Steel Industry to new heights by providing C to C Solution (Concept to Commissioning Solutions) for Iron Making, Steel Melting Shop, Power Plants, Rolling Mill Plants of Long & Flat products for Producing Bar Rolling Mills / Rebars Rolling Mills, Wire Rod Rolling Mills and Section Rolling Mills & Narrow Strips Rolling Mills. The company has earned the name and it’s recognized as leading EPC & EPCF solution provider our main Areas of Activity are as follows: Iron Making projects including DRI Plants, Sinter Plants, Blast Furnaces | Steel making up-to 2-million-ton capacity using Electric Arc Furnaces, Induction Furnaces, Ladle Furnaces, Vacuum Degassing Units, Continuous Casting Machines | Steel Rolling Mill Projects up-to 3,000,000 Tons / Year capacity both for Flat Products & Long Products including Narrow Strip Rolling Mills, Wide Plate Rolling Mills, Stickle Coil Rolling Mills, Re-Bar Rolling Mills, Wire Rod Rolling Mills, Light Section / Profile Rolling Mills, Medium Section / Profile Rolling Mills, Light Section / Profile Rolling Mills Cold Rolling Mills & Processing Lines. Cold Rolling Mills And Skin Pass Mill For Ferrous & Non-Ferrous | Galvanizing Lines (CGL) ( Furnace Type & Wet Flux Type) | Colour Coating Lines (CCL) | Electrolytic Cleaning Line | Tension Levelling Lines (TLL) | Bright Annealing (BA) Line For Stainless Steel | Annealing & Pickling Lines For S.S. | H & T Line | Hot Rolled Coils Slitting Lines | Cold Rolled Coil Slitting Lines | Cut To Length HR, CR And End Lap CTL | Semi Continuous Pickling Lines / Push Pull Pickling Lines | Corrugating Machines | High Speed Trimming-Cum-Rewinding Line | Oil Film Bearings | Service Solutions For Rolling Mills And Process Lines | Modernization Of Plate Rolling Mills | Flexible High-Performance Plants For Hot Strip Mills | Complete Solutions For Electrics And Automation (Level 1, Level 2 & Level 3) | High-Performance Hot Strip Rolling Mills | Reversing Cold Mills | Compact Cold Mills | Multi Roll Mill Stands For Stainless-Steel Strip | Skin-Pass Mills For A Perfect Finish | Hydraulic Systems

2Hi Roughing Mill for Narrow Strip Rolling Mills

4Hi Rolling Mill Stand for Narrow Strip Rolling Mills

4Hi Stand for Cold Rolling Mill

4hi Stand for Narrow Strip Rolling Mill

Backup Roll Assembly for Narrow Strip Rolling Mills

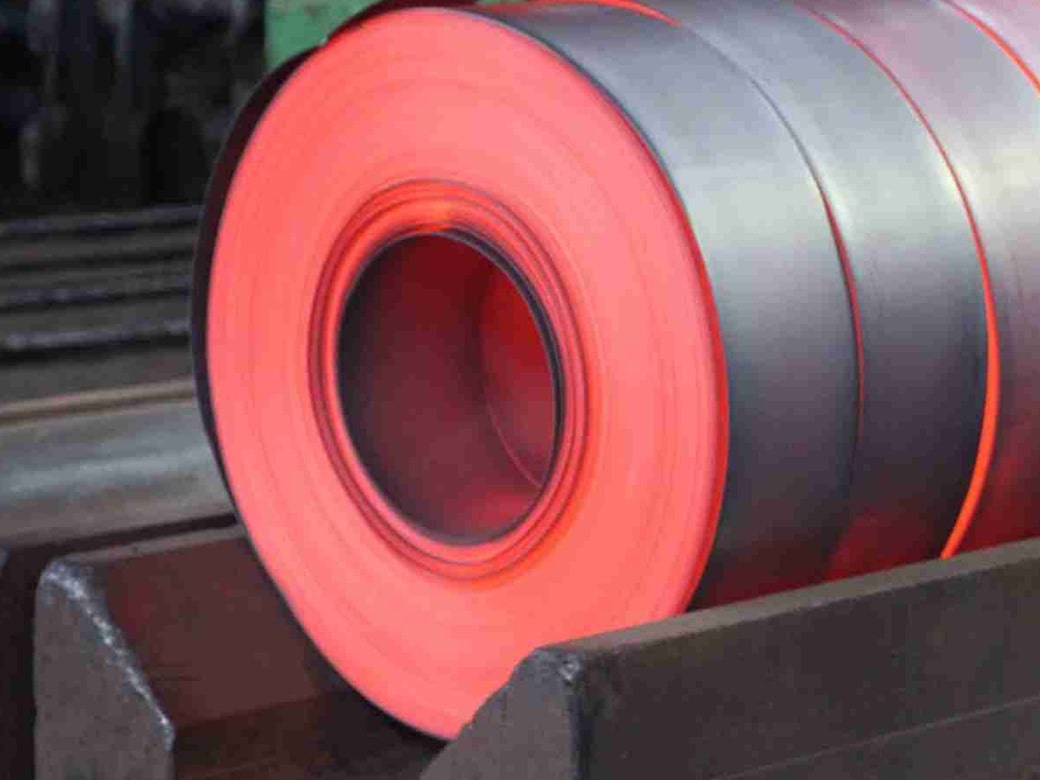

Coils from Narrow Strip Rolling Mill

Drum Shear with Tandem Rolling Mill from Narrow Strip Rolling Mills

Hot Rolled Coils from Narrow Hot Strip Rolling Mills

Hot Strip Rolling Mills

Hot Strip Rolling Mills

Housings for Hot Strip Rolling Mills

Narrow Strip Rolling Mills

Rolls for Narrow Strip Rolling Mills

Roughing Stand for Narrow Strip Rolling Mills

Stand Assembly for Hot Strip Rolling Mills