Preet Brothers Limited | Shearing Machines & Hot Saws | A Preet Enterprises.

PREET manufactures wide range of Shearing machines and Hot saws. Few of them to mention below:

• Crank Type Start / Stop Flying Shears

• Start / Stop Type Flying Shears

• Combined / Rotary Flying Shears

• Continuous Operating Shear

• Cold Shears

• Crop and Cobble Shear for Medium Section

Preet offers a full line of robustly designed, manufactured, and assembled shears including the efficient crop & cobble shear and the high-speed mechanical direct drive shear (flying shear), both of which are used in start & stop applications. Preet also offers high speed rotary shears, drum style shears, and various oscillating and flying shears for bars / blanks cutting “on the fly”, without requiring the stoppage of the bars / blanks travel during the shear cut. Preet also builds the electromechanical for applications where faster cutting speeds are required in high production applications. This device requires no electrical controls, is virtually maintenance free, provides a high-quality cut edge and maximizes knife life. All our shears are available with various optional items such as pinch rolls, tail pushers, sample collectors, quick change knife systems. Our company is one of the few equipment builders supplying equipment to the long product steel rolling mill industries that has an in-house, dedicated engineering workforce with mechanical, electrical and control departments as well as an in-house field service department with 24-hour availability and a dedicated spare parts department. Preet also has a fully staffed 450,000 sq. foot manufacturing facility with CNC machining centers, welding, stress relieving, assembly, paint, wiring, testing, quality control and shipping departments. Preet is a manufacturer of heavy industrial shears for steel and other metals. We design and manufacture a wide range of industrial shears using high-quality materials along with the most advanced technology. We have the ability to build any kind of shearing machine to suit your specific requirements. Benefits: High Strength | Stable Performance | Easy Operation | Convenient Maintenance | Custom Designed for your Application | A one-stop shop to design, build, and install the equipment or its parts | Four Decades of History. Industrial shearing machines can work for decades; however, some parts should be changed to improve the efficiency and productivity of the steel mill. Our engineering team can reverse engineer any parts for a shearing machine such the blade, or any other components no matter how big or small your equipment. Steel rolling mills use Flying Shears for cutting profile metals and bars during the rolling mill process. These can be fully automated with a motor and a heat sensor depending on the application. Custom designed Flying Shears can be semi-automatic or fully automatic depending on customer needs. Steel mills choose to have Flying Shears custom designed based on their own specific needs. Custom designing ensures that their materials are cut precisely to their requirements and will also save money by reducing maintenance. Preet is a manufacturer and service provider for all types of industrial Flying Shears. We are specialists in designing and manufacturing high speed flying shear machines for cutting various steel products such as coils, bars, profile metals, etc. to precise lengths without stopping the cut processing. Our custom-built Flying Shears are specially designed to meet your situation. The design will determine the size of shear, best materials to use, and their thickness and strength. In the past 44 years, Preet has designed and built high-performance machines, employing the most advanced technology, and of the highest quality. Preet designs, manufactures, builds and services two types of Flying Shears: Rotary Shear | Crank Shear. Having a precision flying Shear (cut-to-length) lines make your production plant more productive, faster, safer, and more efficient. The advantages of using Preet Flying Shear for your plant are Energy efficiency | Minimum cost | Most advanced custom designed flying shear | Precise cut-to-length machine | Minimum tooling preparation and higher productivity rates. Cold Shearing machines are used in Steel Mills to cut the finished product to a defined length. Steel facilities use Cold Shears system for all types of bars, rounds, and structural products. Preet custom designs, manufactures, delivers, and set up Cold Shears to: increase production capacity | Improve cutting quality | Improve automation | Reduce maintenance costs | Reduce blade change downtime. Our engineering team can develop high strength capacity Cold Shearing machines with the most advanced technology, for your specific application. Cold Shears are custom designed and built based on a plant’s requirement for strength, automation, and capacity. Depending on the annual production capacity of the plant, cutting force capacity and blade length are determined by engineers at Preet.

PREET BROTHERS LIMITED | LONG PRODUCTS HOT ROLLING MILL DIVISION | A PREET ENTERPRISE

Preet Brothers Limited | Long Product Hot Rolling Mill Division has successfully designed, built and executed small, medium and mega size Hot Rolling Mills projects with annual capacity up to 1,000,000 Tons like: Rebar Rolling Mills, Wire Rod Rolling Mills, Bar Rolling Mills, Light Section Rolling Mills, Medium Section Rolling Mills, Heavy Section Rolling Mills. Besides complete plants Preet Brothers Limited | Long Product Hot Rolling Mill Division also under-take custom built design equipment’s based on the latest technology for various rolling mill equipment and systems like Rebar Rolling Mills | SBQ Rolling Mills | Wire Rod & Bar Rolling Mills | Small Section Rolling Mills | Medium Section Rolling Mills | Heavy Section Rolling Mills On Turnkey Bases (EPC & EP&S). Reheating Furnaces for Rolling Mills | Housingless stands for Hot Rolling Mills | Convertible Housingless Stands for Hot Rolling Mills | Universal Housingless Stands for Section Rolling Mills | Cantilever Stands for Hot Rolling Mills | Wirerod Mono-Block for Hot Rolling Mills | Sizing Mills for Hot Rolling Mills | Crank Shears for Hot Rolling Mills | Flying Shears for Hot Rolling Mills | Crop & Cobble Shears for Hot Rolling Mills | Crank cum Flying Dividing shears for Hot Rolling Mills | Thermo-processing units (TMT Plants) for Hot Rolling Mills | Harden Ground Gears & Gear boxes & Profile Ground Gears & Gear boxes | Entry and Exit Roller Guides Harden & Profile Ground Gears & Gear boxes | Slitting Guide boxes for 2 / 3 / 4 / 5 / 6 slitting Harden & Profile Ground Gears & Gear boxes | Sliding apron (Braking Slide) Rake type Cooling beds Harden & Profile Ground Gears & Gear boxes | Cold Shears of various sizes (150-1500Tons) | Dispatch & Bundling systems | Bar counters | Magnetic Stackers for Section handling | Single / Multi Groove Straighteners for on-line & off-line application in section rolling mill | Hot Saws & Cold Saws for Section Rolling Mill | Roll Changing Robots & Tilters for Rebar Rolling Mills | Preet Brothers Limited Roll-pass designs for slitting, angles, channels, I-beams & H-beams. Latest technology and high productivity of our plants: Guided by these concepts, we supply a complete scope of any green-field rolling mill for long products, as well as upgrading of existing plants. From the initial concept of the plant to commissioning and start-up. Technical department @Preet Brothers Limited, equipped with latest software’s for design and rolling process development, managed by experienced engineers, design machines and full plants according to customer requirements. Roll pass design department and process engineers fully support the design engineers to improve the machines and mill’s performances, through continuous know-how transfer.

300 Ton Cold Shear for Rebar Rolling Mills

600 Ton Cold Shear for Rebar Rolling Mills

600 Ton Cold Shear for Rebar Rolling Mills

850mm Fying Shear for Rebar Rolling Mills

Continuous Shear for High Speed Rebar for Rolling Mills

Crank cum Flying Shear for Rebar Rolling Mills

Crop and Cobble Shear for Wirerod Rolling Mills

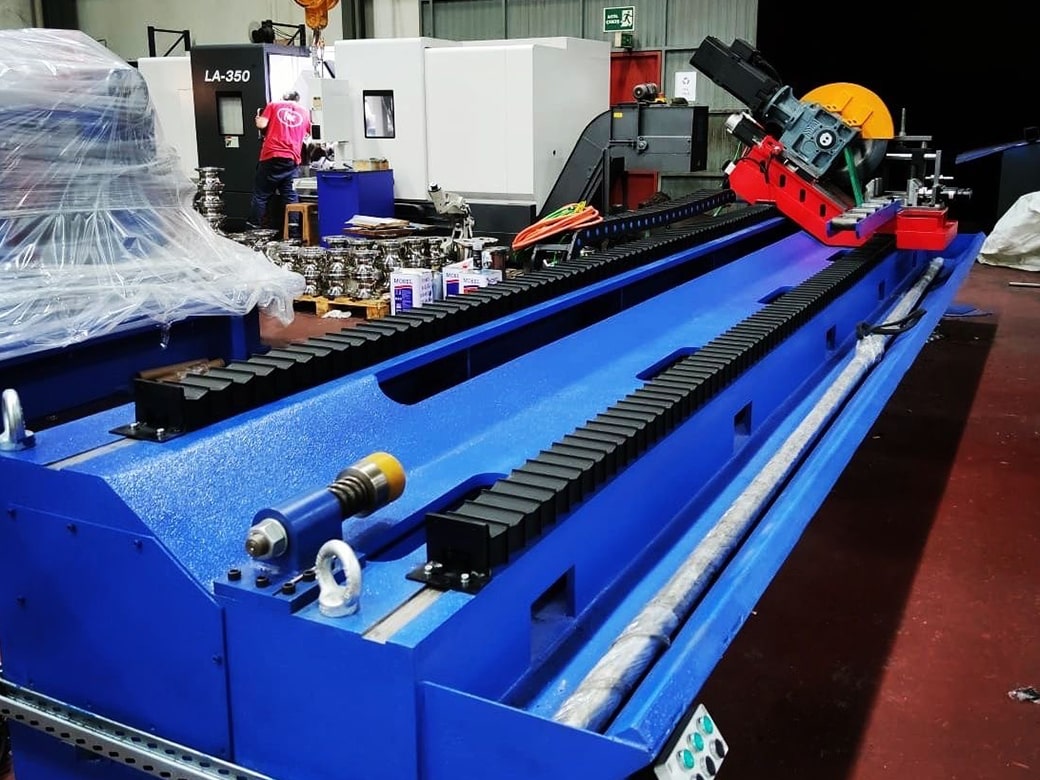

Flying Saw for Pipe Mills

Four Crank Crop cum Cobble Shear for Rebar Rolling Mills

Hot Saws for Section Rolling Mills

1100mm Flying Shear Start and Stop Type for Rebar Rolling Mills

1200mm Four Crank Crop and Cobble Shear for Rebar Rolling Mills

Billet Toggle Shear for Rebar Rolling Mills

Flying Shear for 4 Strand Rebar Rolling Mills